Back to Essential Guide to Precision Farming Tools

JOHN DEERE — ExactApply

Tech Specs: Available starting in 2018 on new John Deere 4-Series Sprayers, the ExactApply intelligent nozzle control system maintains consistent droplet size and pattern through a wide range of speeds, while reducing the potential for overlaps, skips and drift. The system can automatically vary the rate across the entire boom, ensuring the correct amount of material is applied to the right area of the field, even while turning and reduces the number of nozzles needed because of range increases on each nozzle.

Compatibility Index: Available Factory Installed

WOW Factor: An industry exclusive feature is 30 hertz nozzle pulse width modulation, which allows customers to increase their coverage pattern, which is valuable when dealing with chemical-resistant weeds.

TOPCON — Athene Electronic Control Unit (ECU)

Tech Specs: Athene from Topcon is an ISOBUS electronic control unit with an ISO-Universal Terminal (UT) user interface designed to offer spreader control to support granular belt fertilizer spreaders. The system features variable-rate application and section control for spreader start and stop via the controller, application rate control proportional to forward speed based on hydraulic belt speed, the ability to change rate on-the-go and gate height control and monitoring.

Compatibility Index: ISOBUS Certified Component

WOW Factor: Load cells on the scale system allow for auto calibration of the spreader rate controlled every 5 seconds which translates to a deviation of less than 1% in most cases, compared to as much as 8% in the past.

KUHN KRAUSE — Axcent 100.1

Tech Specs: The new Axcent 100.1 precision fertilizer spreader from Kuhn Krause allows for application of a variety of dry fertilizers including urea and lime on 120 foot widths, along with cover crop seeding capabilities. The system also includes a unique application rate control system, which increases the accuracy of applied fertilizers.

WOW Factor: The typical North American spinner spreader measures about 9-10% inefficiency, which equates to 9-10% misapplication of material. The Axcent’s toque sensor system can get to 2% or less misapplication.

SALFORD — ST-10 Applicator

Tech Specs: The ST-10 Applicator from Salford features 2 tanks with a 60/40 split. Each tank feeds into 4 metering sections for a total of 8, giving the system 4 section control at rates up to 600 pounds per acre.

WOW Factor: Eight metering segments (four on each tank) deliver fertilizer to 4 funnels that guide product into a common venturi air stream for the highest possible blending accuracy and efficiency.

PENTAIR — Duo React

Tech Specs: The Duo React is a twin pneumatic valve nozzle body and control system from Pentair that allows either or both valves to spray. Drive at varying speeds and maintain application rate and spray quality by switching between two different nozzle sizes. Variable-rate liquid fertilizer is also accurately applied by selecting appropriate nozzle combinations.

WOW Factor: The system features pneumatic only or electro-pneumatic actuated valve options. The electro-pneumatic body can be used in place of a section control valve to control up to 7 pneumatic nozzle bodies.

GREAT PLAINS MFG. — AccuShot

Tech Specs: AccuShot is a new planter attachment from Great Plains Mfg. with economic, environmental and agronomic benefits. Farmers can deliver the right dose of liquid seed treatment, right in the furrow, right at planting time. The system is ideal for starter fertilizer or growth promoter application and can minimize waste because each seed receives precisely what it needs and nothing more, regardless of how fast or slow the tractor travels or variance in seed population.

WOW Factor: The system can maximize early corn development and optimize long-term health. Starter fertilizer is injected at a close — yet safe — distance from each seed at planting, which means 100% of the fertilizer is immediately available to the growing feeder roots.

360 YIELD CENTER — 360 Y-Drop

Tech Specs: The narrow row design of the 360 Y-Drop from 360 Yield Center with its 4-position adjustable arms, allows for precision placement of nitrogen (N) and other nutrients like phosphorus, potassium and micronutrients in 15-36 inch corn rows. The newly designed shield keeps leaves from wrapping on the riser or hoses and the breakaway mounting brackets allow for easier navigation across hills and uneven terrain. An additional easy add on to the system is 360 Undercover, an in-canopy fungicide and insecticide application system. The 4 multi-directional spray nozzles on each unit allow for customized spray patterns and the ability to gain 150 degrees of horizontal spray application. The unique application system can be used in corn, seed corn, soybeans, wheat, cotton and sugarbeets and is ideal for simultaneous application of N and fungicide/insecticide application in dual tank sprayers.

Compatibility Index: Exclusively Aftermarket Product

WOW Factor: The unique application tool places N 2-3 inches from the base of the corn plant for maximum uptake and extends the application window so farmers can supply N to their corn when it needs it most. Research shows that the system boosts yields by 13.8 bushels per acre compared to conventional N application methods. The addition of 360 Undercover takes plant health application down into the canopy where it delivers targeted application of fungicides and insecticides where it’s most effective.

RAVEN INDUSTRIES — Hawkeye Nozzle Control

Tech Specs: The Hawkeye system from Raven Industries is a pressure based product control system that allows for precise sprayer application in a variety of conditions, getting the most out of every nozzle in the field. Each nozzle is controlled by its own individual pulse width modulation (PWM) valve giving operators a consistent spray pattern across the boom as speed and conditions change. Nozzle-by-nozzle turn compensation minimizes misapplication and virtual sections provide more control and higher ROI than traditional shut-off systems. The system is simple to install and calibrate, and upgrades are done via software, eliminating any need to remove and reinstall hardware components. With Hawkeye HD, users can utilize individual nozzle on/off to reduce costly skips or overlaps across the width of the boom. Also compatible with Raven’s Sidekick Pro Direct Injection, the system allows operators to use up to 5 injection systems on one machine through the Viper 4+ platform.

Compatibility Index: ISOBUS Certified Component, Available Factory Installed

WOW Factor: The system helps combat weed resistance by providing a consistent spray pattern and droplet size based on the needs of the user. Despite speed or conditions, the pressure stays consistent and gives operators better coverage across the width of the boom. The base system provides turn compensation and virtual sections for additional precision and control. The base system allows for 20 hours of testing in the field of the Hawkeye HD individual on/off upgrade at no additional cost.

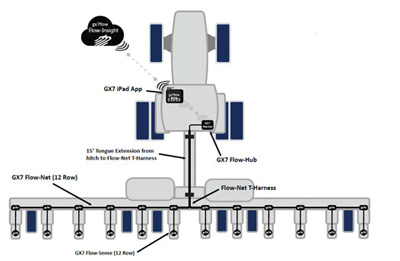

AgXCEL PRECISION LIQUID FERTILIZER SOLUTIONS — GX7d Row Monitoring

Tech Specs: The GX7d Row Monitoring Solution from AgXcel intelligently monitors liquid application on every row of any implement. Should a row placement applicator become plugged or congested, the in-cab monitor will detect the stop or reduction of flow and alert the user as to which specific row is having flow issues.

Compatibility Index: Available Factory Installed

WOW Factor: The system tracks all liquid application with GPS and maps the application in real-time to help avoid over- or under-application.

MICRO-TRAK SYSTEMS INC. — 3Rive 3D

Tech Specs: A insecticide delivery platform specifically designed to apply Capture 3Rive 3D Insecticide in-furrow, the platform from Micro-Trak Systems Inc. features a 130 gallon water tank, a 30 gallon chemical tank and state-of-the-art control and blockage monitor systems. The control system is available in either stand-alone console format or ISOBUS platform. When combined with water and air, the chemical expands up to 50 times in volume to provide a continuous 3D zone of protection in-furrow, protecting against corn rootworms, cutworms, wireworms, grubs and other seedling pests. The system easily mounts to all major planter brands and the product is delivered in-furrow through modified Keeton Seed Firmers, Rebounder Seed Covers or John Deere ExactEmerge brackets.

Compatibility Index: Exclusively Aftermarket Product

WOW Factor: The system allows farmers to cover up to 500 acres per fill, saving water, fuel, labor and time. When compared to dry granular insecticides, issues like container handling, inconvenience, high water volume and weight on the planter are eliminated The system refills faster, runs longer between refills and treats more acres from each fill while eliminating moving and lifting bulky dry granular boxes.

Post a comment

Report Abusive Comment