The 2020 recipient of Precision Farming Dealer’s eighth annual Most Valuable Dealership is RDO Equipment Co., based in Fargo, N.D.

In total, 18 U.S. and Canadian dealerships including large and small farm equipment dealership groups with precision departments, independent precision operations and co-ops were nominated by their farm customers, precision equipment suppliers and their own employees.

Evaluated criteria included precision farming sales growth and diversity, along with how each nominee is generating revenue from hardware, software and precision service. Less quantifiable elements that define the best precision farming dealership, such as employee training, performance standards, innovation, sustainability and community involvement were also considered.

Nominate a Dealership for the 2021 MVD

It’s never too early to nominate candidates for next year’s Precision Farming Dealer Most Valuable Dealership program. We’re inviting you to participate by submitting entries for precision farming dealers and please nominate all the dealers you feel are worthy of consideration by our judges.

There is no limit to the number of nominations you can submit, and if you prefer, we will not reveal to the dealers who nominated them for this honor.

Open to all precision farming dealers in the U.S. and Canada, Precision Farming Dealer will again be recognizing the organization that demonstrates the best in sales, service and support of precision farming technology.

Simply complete the nomination form at www.PrecisionFarmingDealer.com to be considered for this recognition in 2021. Or email nominations to Jack Zemlicka at jzemlicka@lessitermedia.com

We hope that you’ll choose to participate in this program and help showcase the finest precision farming dealers in our industry!

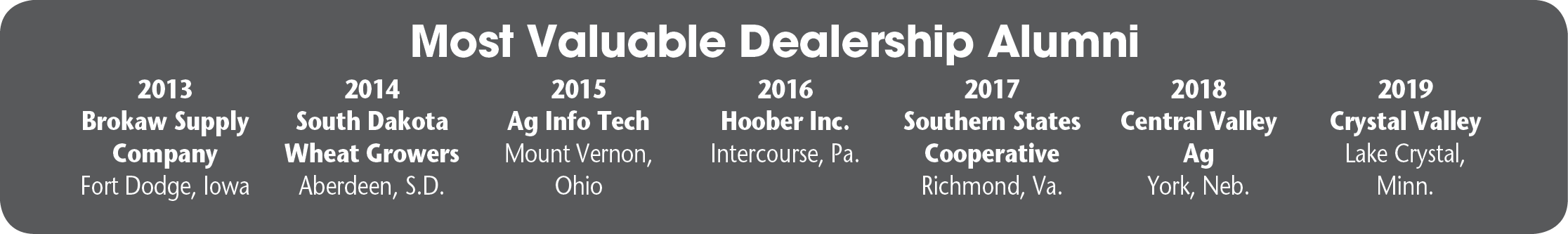

Previous recipients showcased the diversity of dealerships carving out a successful niche in precision farming, and 2020 highlighted the second large ag equipment dealership in RDO Equipment, and the first John Deere outfit to capture the honor.

RDO is also the first dealership to also be recognized by our sister publication Farm Equipment’s Dealership of the Year (2010), at a time when the company operated about half of its current 35 ag locations. Executive management also had the foresight back then to realize internal investment and expansion in technology training would be essential to the evolution of the dealership.

This philosophy has helped shape and define the development of RDO’s precision farming business, which has grown its ag technology service sales by 80% during the last 3 years and has averaged more than $5.5 million in precision ag component sales during the last 6 years.

While facing the same recent economic challenges as the majority of equipment dealers — large and small — RDO has worked to creatively maneuver through the downtown. This includes expanding on precision problem-solving solutions as a larger source of recurring revenue and increasing customer engagement efforts to meets the need of a diverse customer base.

“We have 30 people on our precision team and our focus is on being diverse and leveraging each other’s expertise to service our customers, but also to avoid getting burned out,” says Joel Kaczynski, product specialist manager. “We take a centralized approach to managing the team, which is essential to cover the diversity we see from corn and soybeans in Minnesota, down to strawberries and lettuce in California.”

Leveraging Service Diversity & Delivery as Precision Difference Makers for Customers

Emphasis on solutions-based selling and a farmer-first philosophy with ag technology support has allowed RDO Equipment Co. to effectively service more than 3 million precision acres across 8 states.

RDO Equipment Co.

Founded: 1968

Ag Locations: 35 in 8 states, broken into 3 regions. Midwest: (Minnesota, North Dakota, South Dakota); Northwest: (Montana, Oregon, Washington); Southwest: (Arizona, California)

Employees: 2,500. This includes 30 precision employees, distributed throughout the dealership’s production ag locations.

Precision Lines Carried/Used: John Deere, Raven, 360 Yield Center, Montag, Vision Robotics, Sentera, SureFire Ag Systems, Hagie, New Leader, Dawn Equipment, Dickey-john, Orthman, Intelligent Ag Solutions, Pessl Instruments and Precision Terrain Solutions

*3-Year Precision Sales Breakdown

(Fiscal Year):

3-Year Precision Service Sales

(Fiscal Year):

Walking through the halls of RDO Equipment Co.’s administrative headquarters in Fargo, N.D., one of the recurring reminders of the company’s culture are the core values. Partner with Employees. Build Customers for Life. Create Opportunities. We Do what We Say. Play to Win.

The words are much more than window dressing and are especially aligned with the dealership’s precision farming goals of forging lasting business bonds with customers, via responsive, reliable service.

“Our customers are faced with decreasing margins and time is critical with the small window the weather allows them for field preparation, planting, application and harvest,” says Joel Kaczynski, product specialist manager. “They can’t afford to have technology slow them down and narrow the window of opportunity. The dealers who offer the most reliable technology and have the ability to support it efficiently are in the lead today and will continue to be in the future.”

Kaczynski, who joined RDO in 2004, leads a team of nearly 30 product specialists in the dealership’s Midwest (Minnesota, North Dakota, South Dakota), Southwest (Arizona, California) and Northwest (Montana, Oregon, Washington) regions.

Visiting with Kaczynski and a few members of the Midwest precision team, there was a consistency in their understanding and application of RDO’s foundational business principles. From evolution of the dealership’s suite of Fleet Shield Services, to a growing arsenal of customer engagement tools, RDO’s precision hardware and service sales contributed nearly $8 million to the bottom line in fiscal year 2019.

Service-Centric Selling

Momentum continues to grow for dealers developing and deploying flexible, customized precision service programs designed to deliver recurring revenue. With no universal template to draw from, especially to satisfy the needs of a diverse customer base, RDO launched its branded Fleet Shield Services in 2014.

The initial program was basic and broad, including call center support, one-on-one training for Deere’s Apex software, GreenStar product training and a precision ag farm evaluation report.

Dealer Takeaways

- Specialized precision services offer targeted, yet diverse options to accommodate technology needs of a diverse customer base.

- Leverage digital media tools, including podcasts, as brand-building for your precision team and to engage customers.

- Understand the agronomic side of equipment sales and look to have an internal expert to explain the connection to customers.

“The call center was our biggest take the first couple of years because, for $250, customers could get that unlimited phone support,” says Tony Kramer, product specialist supervisor, who joined the dealership in 2010. “Initially, it was tough to get farmers to cross that line into paying for that support, but it was a window into other services. We had about 80 customers enrolled in the call center that first year, but it’s not something we even charge for anymore as we’ve evolved our services.”

RDO has several customer support teams which started with a parts call center in 2010, designed to be the first line of troubleshooting and problem-solving for both agriculture and construction customers. The service is free to RDO customers and of the more than 75,000 calls received in 2019, about 6,500 were precision farming related.

Despite the customer traction with phone support services, getting whole dealership buy-in on the Fleet Shield Services program required a cultural change, in terms of how the precision programs were marketed, priced and sold. One of the challenges was getting account managers (equipment salespeople) on board with including technology needs into the conversation they had with customers.

“It’s easy to see the money coming in from iron sales, but understanding the significance of the first time a customer experiences a 1-hour equipment start-up vs. 2 days — that’s where our value proposition is,” says Ben Hilde, product specialist based out of RDO’s Hawley, Minn., location. “We want to be proactive with our precision services, reduce customer frustration before it even happens.”

Fleet Shield Services programs today include on-farm product operation training ($500 per session), equipment optimization ($400 per unit in-field) and field start-up ($600 per unit, pre-season), machine health monitoring through JDLink ($100-$250 per machine), Data Management, ($1,000 per farm) and Field Connect moisture monitoring ($100-1,000 per probe).

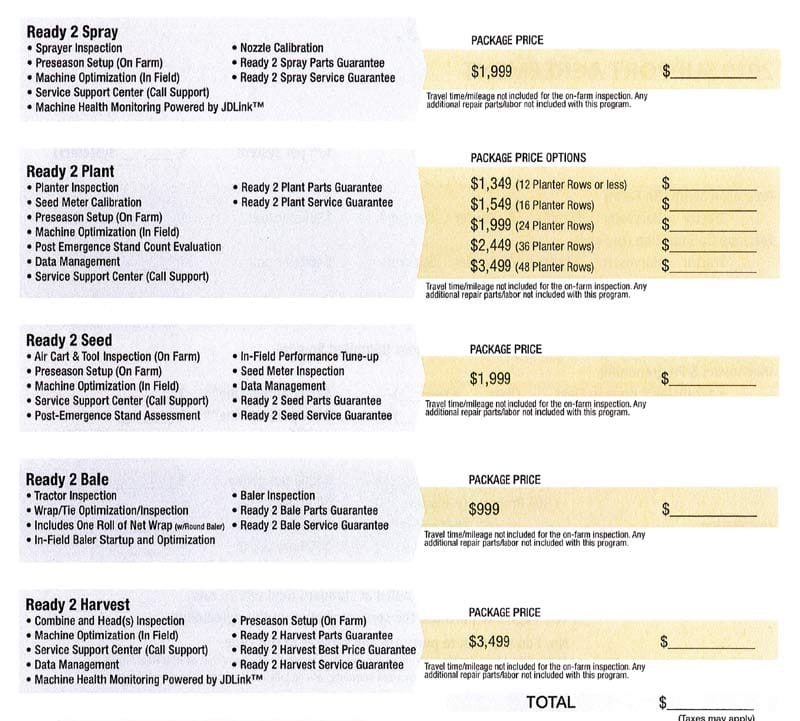

Fig. 1. RDO’s Ready 2 precision service programs, launched in 2017, provide specific seasonal support options for customers, The first offering was the Ready 2 Plant program which includes inspection, seed meter calibration, post emergence stand count, data management, phone support and a parts and service guarantee.

Extension vs. Shadow

RDO eventually saw the need for more specific precision service options that focused on seasonal customer needs including planting, spraying and harvesting.

“If we were doing a planter startup in the field and found that the machine needs a lot of work done to it, we wanted to offer a comprehensive package of support to our customers,” Kaczynski says. “It goes back to putting one of our core values, Build Customers for Life, into practice. And in doing so, we look at our customers that we’re truly partnering with which is why we want to take a targeted approach in identifying their needs.”

With that philosophy in mind, RDO formally launched its exclusively-branded Ready 2 service programs in 2017, with the first offering being the Ready 2 Plant program. The annual package includes inspection, seed meter calibration, post emergence stand count, data management, phone support and a parts and service guarantee.

The pricing structure is primarily per-row for planters, with the average annual cost for a 12-row model being about $1,300 (see Fig. 1 on page 4). The key to selling the program is checking off each benefit for the customer and then tying them all together at the end of the season, says Hilde.

Understanding of the agronomic implications that our machines have on a given field helps provide a full solution to the customer. Sometimes it can have an economic impact. But it will always have an agronomic impact…

“Some farmers feel it’s very valuable to test run those row units every year to maximize the efficiency of that planter before it gets to the field,” he says. “A lot of times we’ll see a direct result of that in the stand counts we do as part of the Ready 2 Plant program.

“We’re obviously not guaranteeing their seed to emerge better than it is, but we want to make sure that planter performed mechanically the way it should. Planting windows are critical. We all lived that in 2019. So when we’re showing customers that an investment of $600 for a start-up or a $2,000 Ready 2 Plant service can be pretty much pennies vs. getting that crop planted and realizing that yield potential, that’s huge.”

RDO has expanded its Ready 2 program to included comprehensive packages for spraying ($1,999), seeding ($1,999), baling ($999) and harvest ($3,499). In addition to broadening the scope of recurring revenue opportunities, the packages, which have 97 customers enrolled, have enhanced collaboration with other departments.

“The precision team had essentially been a shadow of the sales team or the service team,” says Kramer. “Now, it’s just an extension of those teams, whether it parts, service or sales. Our overall objective within the company is to be a total solutions provider for our customers.”

Internal communication is key among RDO’s precision team, including from left to right, Tony Kramer, product specialist supervisor, Joel Kaczynski, product specialist manager and Jacob Maurer, staff agronomist. Embracing the dealership’s 5 core values, the precision business accounted for nearly $8 million in sales in fiscal year 2019.

Equipment Agronomy

Another arm of RDO’s precision business is its agronomy team, which includes 2 agronomists and 4 certified crop advisors. While some Deere dealerships have directly incorporated agronomic services into their business model, RDO’s approach is different.

They don’t directly generate revenue from agronomic services, and work more closely with equipment, conducting field trials and compiling data from test plots, while also serving as internal agronomic experts for the precision, parts, sales and service departments.

“Our role is not like a traditional agronomist, and we don’t actually compete with the local guys already working with our customers,” says Jacob Maurer, staff agronomist for the Midwest Region. “We don’t sell recommendations and we don’t do traditional crop scouting. But my understanding of the agronomic implications that our machines have on a given field helps provide a full solution to the customer. Sometimes it can have an economic impact. But it will always have an agronomic impact.”

Connecting with Customers to Build a Personal Precision Brand

RDO Equipment Co.’s precision team has embraced new media as effective ways to reach and communicate with customers. Product specialist Tony Kramer leads the production efforts on the dealership’s Agriculture Technology Podcast, a bi-monthly program covering various ag tech topics and featuring customers, manufacturing partners and fellow precision team members.

“We’re about 5 years into production now with the podcast and we really felt it was a unique opportunity to get information out there about different types of technology or maybe different features of equipment related to technology,” Kramer says. “There’s a lot of information when it comes to ag technology and what’s being introduced. Sometimes it doesn’t get promoted or marketed as well as it should and that’s where the podcast serves as a marketing vehicle not only for us, but the products and services we offer.”

There are agronomic elements rolled into RDO’s Ready 2 programs, which is where the expertise of Maurer and the rest of the team is especially valuable. Accurate collection and accessibility to a customer’s other trusted advisors are responsibilities of RDO’s agronomic team.

“We tie agronomics into our equipment,” Maurer says. “Every single machine that we have is collecting an agronomic data layer, or we’re doing some kind of agronomic function, whether we’re planting a seed or we are sizing crop residue or we could be out making an application.”

Learning Lab

RDO ties each if its precision-specific teams together with an internal training program. The e-learning portal is managed by the dealership’s Learning and Development Team.

The system provides courses on agronomy, precision agriculture and equipment and also includes a tracking system that records these courses and external trainings team members take. But hands-on learning is also critical to the learning curve of RDO’s precision team.

In 2018, the dealership partnered with the North Dakota State College of Science (NDSCS) to develop its Land Lab program. The school received a donation of 91 acres, rent-free for 3 years from Mary Kosel and Linda Patterson, to be used in support of classroom curriculum for agriculture students and works with RDO to develop test plots and do trial runs with equipment.

The arrangement gives RDO’s precision team first-hand experience testing equipment and various methods of field preparation, planting, spraying and harvesting. During field activities, NDSCS students are invited to participate and discuss the events taking place in the field.

Delivering Ag Tech Support for High-Value Crops

Sarah Hill, Associate Editor

The RDO Equipment Co., precision team that is spread across different regions of the U.S., works hard to meet their diverse customers’ expectations. In the Southwest region of the country that means working with growers who are producing very different crops from the corn and soybeans grown in the Midwest.

According to Saul Amezquita, precision product specialist supervisor for Arizona and Southwest California, RDO customers in those areas primarily use precision technology for ground preparation, planting and spraying. Amezquita supervises 3 precision employees who cover 7 stores in the region.

“Harvesting is a more hands-on process, with no machinery involved,” he says. “These are high-value crops such as lettuce, spinach, celery, broccoli, cauliflower, etc.”

RDO customers in the Southwest utilize GPS to maximize the number of rows available per acre. Then they utilize variable-rate for spraying to ensure that product is applied exactly where it is needed, in addition to sidedressing.

“Here in the Southwest, farms operate more like a corporate business,” says Amezquita, who is based in Yuma, Ariz. “These companies run thousands of acres, and they rely on their managers to ensure that the job gets done by making the right decision at the right time. One powerful tool we provided is an equipment management solution based on a telematics system designed to remotely connect owners and managers to their equipment, providing alerts and machine information including location, utilization, performance and maintenance data to manage where and how equipment is being used.

“Also, my team provides operator training to maximize the potential of the machine and precision system being used. We help the seasonal worker understand how the machine can be used by doing one-on-one, hands-on training.”

Farmers in the region face challenges beyond dealing with the weather and commodity prices, according to Amezquita. Their main concerns are the labor rate and dealing with the minimum wage that’s going up, he says.

“Growers are trying to figure out how to transition to a more automated way of doing business,” Amezquita says. “RDO works to keep building on that so we can help our customers with technology adoption. Technology adoption will be the biggest challenge in the area, but it’s coming very quickly.”

Amezquita forecasts that data management and automated documentation of field activities will be crucial in the future. “We have all the technology to do that, but we don’t need it yet,” he observes. “Further regulations might push farmers to document more and do a more thorough job of documentation.”

“Our number one goal with the Land Lab is to better educate the students and get them real life, hands-on experience,” Kramer says. “The first year, we did planting speed trials with our ExactEmerge planters. We were planting passes anywhere from 5-12 mph and we wanted to see if there’s a yield impact based on the speed that we were traveling and planting.”

In 2019, the Land Lab was used to experiment with planting populations and row spacings, trials which Kramer says will help build a database of information to evaluate and compare year-to-year.

What Suppliers Say About RDO Equipment Co…

The team at RDO Equipment has been integral in helping Vision Robotics redesign their equipment to better meet customers’ needs, says Tony Koselka, company founder. He has worked with RDO Equipment Co’s., precision team for the past 2 years.

“We’re a small company, and RDO has stepped in to help do final assembly on some of our equipment to get it out the door sooner,” Koselka adds. “They’ve really stepped up and been hands on.”

Koselka says that the precision team at RDO has assisted Vision Robotics with improving their manufacturing distribution and serving as an intermediary to understand the issues growers may encounter when using their equipment.

“They can communicate easily with us as the middleman,” Koselka says. “We have a close developmental and influential relationship.”

The dealership has even taken the responsibility of training their own team members on using and servicing Vision Robotics equipment, according to Koselka.

“We want it to be a clean, open platform and clear communication with no roadblocks,” Kramer says. “We want to be transparent with what we learn.”

Thus far, collected data from Land Lab results have been used in customer conversations about equipment capabilities and limitations. Kramer notes that short-term, the data has supported ROI-driven discussions about planting equipment and technology, but there are longer-term goals with the program.

“The big picture is to get the customers out to that Land Lab field and let them see firsthand, what we’re doing, whether it’s stand counts or just getting a feel for what we did in a real life scenario,” he says. “For the data, we’re compiling it in the John Deere Operations Center and created a view only account for anybody who is interested to go in and take a look at it.”

Check out the 2020 MVD Video Series

Visit www.PrecisionFarmingDealer.com to watch exclusive interviews with members of the RDO Equipment Co. precision team. Filmed at the dealership’s locations in Minnesota and North Dakota, these videos capture the innovative strategies and proven practices utilized by the 2020 Most Valuable Dealership.

Topics Include:

- Establishing At-the-Ready Precision Support Programs

- Driving Equipment Performance with Analytical Agronomy

- How to Make Precision ‘Insurance’ a Sellable Service

- Creating Customized Precision Solutions for Diverse Customers

- Getting Inside the RDO Equipment Co. Land Lab

- Building Customer Bonds with a Marketable Precision Message

Post a comment

Report Abusive Comment