Back to Essential Guide to Precision Farming Tools

eDriveXD and eDriveXC

Tech Specs: Outback Guidance recently introduced two next generation auto-steering systems in the company’s eDrive auto-steer series. The eDriveXD offers decimeter-level accuracy and the new high-performance eDriveXC with centimeter accuracy. The eDriveX Series products are engineered for compatibility with a wide variety of brands of tractors, sprayers, spreaders and combines via hydraulic or electric steer interfaces. Both systems are designed to be fully compatible with the Outback Max or Outback STX advanced GPS guidance terminals.

WOW Factor: Used with a hydraulic interface or with the eDriveESi system, the eDriveX series products provide straight, contour and circle pivot modes for maximum versatility and are available in model-specific installation kits for quick installation on over 2,600 makes and models of equipment.

NextSwath

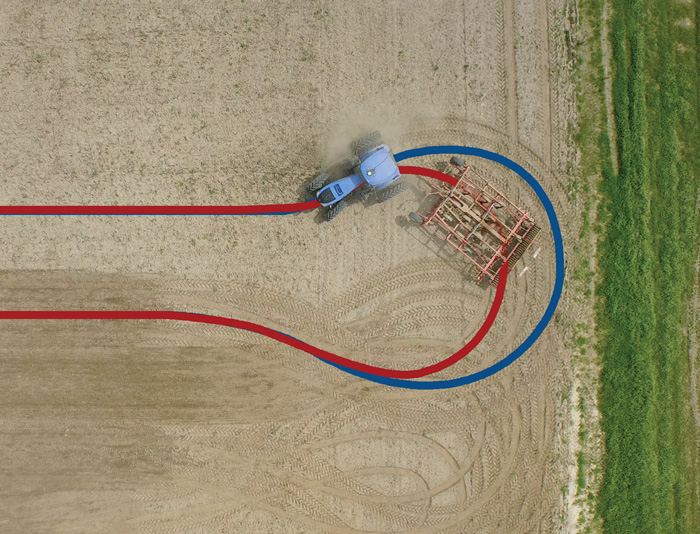

Tech Specs: When used on the TMX-2050 display, Autopilot includes Trimble NextSwath end-of-row turn technology to automatically calculate and execute the best possible path to turn around a vehicle and approach the next crop row or swath with the implement precisely aligned to begin working. By automating the end-of-row turn process, the technology can improve the operator’s performance, eliminate towed implement undershooting or overshooting and minimize skips and overlaps when lining up for the next row. It is well suited for field tasks that use a pull-behind implement or require multiple applications during the crop season such as nutrient spraying. The ability to make tighter end-of-row turns with pull-type implements can also reduce the headland space needed at the end of the field for turning machines.

WOW Factor: Efficient and consistent end-of-row turning saves time and increases productivity, enabling the grower to approach the next line with a turn that is best suited for their vehicle and implement configuration. The technology also saves fuel costs, reduces crop damage and compaction at field boundaries, which can increase yield.

IntelliCruise Tractor/Baler Automation

Tech Specs: New Holland’s new IntelliCruise ISOBUS Class 3 automation enables its BigBaler to control the speed of its T7 series Auto Command tractor to achieve a constant feed rate or flake thickness while baling. The system allows the baler to run at optimal performance by controlling the speed of the tractor. When operated in charge control, the system automatically matches the tractor’s forward speed to crop load at the BigBaler. A charge sensor on the stuffer constantly monitors the bale charges — or slices — delivered to the bale chamber. The system measures the demand placed on the baler (from crop yield) and adjusts tractor forward speed for optimal crop feeding. In areas with lighter crop, forward speed automatically increases so operators consistently work at the capacity they specify. When operated in slice control, tractor speed is adapted based on slice thickness to strive to obtain a user defined amount of slices.

Compatibility Index: Available Factory Installed

WOW Factor: Dramatically reduces fatigue because fewer operator interventions are needed, up to 9% higher capacity and productivity over an inexperienced or fatigued operator and lower fuel consumption resulting in lower production costs.

![[Technology Corner] Pessl Instruments CEO Talks Dealer Benefits From Lindsay Corp. Investment](https://www.precisionfarmingdealer.com/ext/resources/2024/04/25/Pessl-Instruments-CEO-Talks-Dealer-Benefits-From-Lindsay-Corp.-Investment.png?height=290&t=1714145250&width=400)

Post a comment

Report Abusive Comment