While eliminating service stress during busy season seems almost impossible, there are creative ways to prevent burnout and put valuable hours back on the clock. Abby Weltzien of Swiderski Equipment, Chad Baker of Baker Precision Planter Works and Joe Anderson of Johnson Tractor have each found their own formula for minimizing stress when planting season rolls around. The formula includes mentorship programs for young technicians, clinics to train customers and co-workers and service agreements that often solve problems before busy season even starts.

Find the Right People

Hire the right people and stress levels will naturally plummet. Easier said than done, says Weltzien, precision solutions service and parts manager for 5-store New Holland dealer Swiderski Equipment in central Wisconsin.

“Where do you find precision techs?” Weltzien says. “If our ideal candidate walked through the door today, we’d hire them in a heartbeat. But that just doesn’t happen. At Swiderski Equipment, we’ve found success with home-grown talent.”

Finding young recruits fresh out of high school or college with limited professional experience and working them into a 3-year mentorship program has paid off for Weltzien’s team. The mentees work closely with experienced salespeople and lead technicians, learning the ropes during real service calls. It’s often sink or swim in those first few months.

“If they can make it through that first year, they’re going to walk through the door in year 2 with confidence because they know what to expect,” Weltzien says. “They know who to call when there’s a problem. They’re doing installations on their own. They’re going on the road and they’re handling phone support. They’re doing everything. Maybe they made a mistake on an installation in year 1, but they’ve learned to pivot and not make that same mistake twice.”

“Our customers must attend a clinic for us to sell them a service agreement…”

The mentorship program only works if team leaders are willing to invest their time and effort in guiding the young technicians, Weltzien says, like a coaching staff practicing patience with freshmen going through growing pains.

Finding the right people isn’t as much of an issue for Chad Baker because he’s basically a one-man band as owner of Orangeville, Ill., independent dealer Baker Precision Planter Works.

“I handle pretty much everything on most days — sales, service and support,” says Baker, who bought the Precision Planting dealership with his dad in 2008. “My wife takes care of payroll and all the bookkeeping. We have 1 full-time technician who we hired in June 2023, and we have a couple part-time employees who help in the shop.”

Educate Customers & Staff

Baker can’t clone himself, so it helps when his customers reach for a wrench instead of a phone. He hosts free monitor clinics every March to prepare customers for growing season.

“We’ve been hosting monitor clinics for about 15 years now,” Baker says. “It’s a 2-day clinic. The first day focuses on our Gen 1 and Gen 2 monitors. Our second day is for Gen 3 monitors, and we dive more into diagnostics, connection issues, plugins and more. We’ve tried to find ways to keep it fresh and new every year.

“This year we might focus more on wear parts because that’s something growers often overlook. One of our customers ran an ExactEmerge planter across 2,000 acres for 6 years and he never changed the disc openers. He didn’t even know how to set them up. We’re finding that we just need to educate the customers more in our region.”

Dealer-to-Dealer Discussion

Abby Weltzien, Joe Anderson and Chad Baker participated in a service stress alleviation panel discussion at the 2024 Precision Farming Dealer Summit in Indianapolis, Ind. One of their peers in the audience asked them about the best ways to keep technicians engaged and fresh during busy season.

“It’s not the perfect solution, but during busy season we have on-call time for technicians,” Weltzien responded. “2 technicians are on call together, and then the following week it’s the other 3 technicians. Then after the busy season we offer 4-day work weeks. Half the team is off Monday, and the other half is off Friday. So, they can make up for some of the time at home they missed during spring.”

“We offer a bonus at the end of the season,” Anderson said. “Paying them back for working those extra hours. We also don’t force anybody to work on Sundays. We have a few technicians who do work on Sunday, I’m 1 of them, but it’s mainly phone support.”

“I don’t really have an answer because it’s just me,” Baker said. “I minimize my own stress.”

Customer clinics are most impactful when they’re service-led rather than sales-led, says Joe Anderson, precision farming specialist for 9-store Case IH dealer Johnson Tractor based in Janesville, Wis.

“The salespeople can talk to customers during lunch or follow up after the clinics, but our service technicians have to be the ones leading the clinics,” Anderson says. “The technicians show the customers how to fix things, and what they need to look for when something goes wrong. That helps minimize the number of calls we get in the spring and fall.”

Johnson Tractor hosts clinics in the winter, spring and fall, each focusing on different pieces of equipment — planters in the spring, combines in early fall and displays, data management and more in the winter. For the first time in 2024, they’re also hosting a ride-and-drive style clinic with Raven Cart automation. Anderson always encourages his co-workers to attend clinics, especially salespeople.

“If you can train the sales staff on the basics, there’s a good chance they can alleviate stress by taking some of the service calls that come in,” Anderson says. “It’s important to get your salespeople in front of the technology. It’s also a good idea to tag team farm visits with them.”

Customer clinics have proven to decrease call volume in the spring for Swiderski Equipment, Johnson Tractor and Baker Precision Planter Works. Joe Anderson encourages members of his sales staff to attend the clinics, so they become familiar enough with new technology to handle service calls during busy season.

Weltzien agrees that clinics cut down on calls, so much so that they’ve become mandatory as part of Swiderski’s service agreements.

“Our customers must attend a clinic for us to sell them a service agreement,” Weltzien says. “It’s a way to bring them onto our service team and teach them what we know. They won’t grasp everything, but they’ll take some knowledge back to their own operation and it will give them confidence in what they’re doing.”

Swiderski Equipment offers clinics on planters, monitors, factory guidance systems, data and telematics. Weltzien is also on board with the idea of inviting OEMs and vendors to participate, even though it might seem “salesy” to some.

“It’s a great way to show the customer that there’s more to our company than just the 1 technician or salesperson they normally see,” Weltzien says. “The customer knows that if one of us gets busy, they have somebody else to rely on, and there’s a wealth of knowledge for them to tap into.”

Strategic Service Agreements

Weltzien’s team consisted of only 3 salespeople and 1 technician when she started working for Swiderski Equipment in 2019. Now, she has 11 people on staff, including 5 technicians.

“Why did we decide that we needed to grow from 1 technician to 5? Because of our service agreements,” Weltzien says.

Swiderski’s service agreements cover everything from planters and GPS to sprayers and combines. The agreements were an overnight hit with customers, but they ultimately led to unsustainable workloads. The problem came to a head in spring 2022 when the average workweek for technicians ballooned to just shy of 100 hours across 6 weeks. Weltzien knew the customer had to meet them halfway, or they’d risk losing good people to burnout. They found a solution in the form of mandatory planter inspections, in addition to customer clinics.

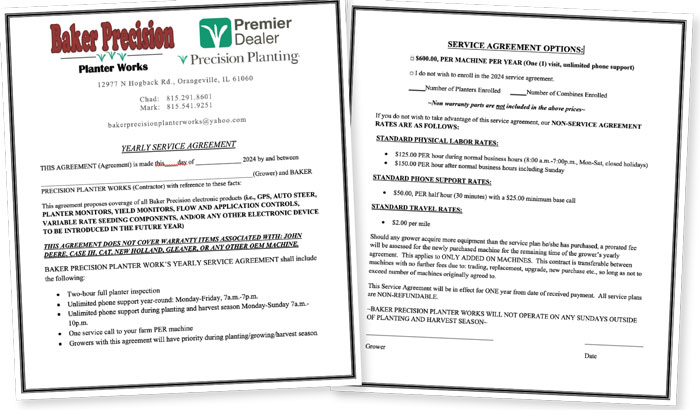

Chad Baker’s service agreement has led to more revenue and less service stress for his independent dealership. The $600-contract gets customers a 2-hour planter inspection, 1 in-season visit and unlimited phone support. Photo by: Chad Baker

“We keep it very reasonable at $50 a row, so a 12-row planter is $600,” Weltzien says. “The mandatory inspections keep our shop active. This gets the technicians in front of different units, so that when the customer calls in the spring, they have a better understanding of what they’re facing. When the technician is done, they give me their findings report. From there we sit down with the customer and go over what we found. For us, it’s all about finding potential failures before they become an emergency in the field.”

Weltzien was nervous about how customers would respond to mandatory planter inspections. Would they tell them to go fly a kite, or would they be on board?

“To my surprise, inspections skyrocketed,” Weltzien says. “They went from 21% in 2022 to 84% in 2023. It resulted in less service calls after hours and on Sundays. We fixed more potential failures than ever before.”

Baker has noticed a similar impact from his annual service agreements, which he offers to customers for $600 per machine. The agreement focuses specifically on Precision Planting equipment, includes a 2-hour, in-season planter inspection, 1 additional in-season service call and unlimited phone support.

“We need to educate the customers more…”

“With the planter inspections, I want to get all the gremlins worked out of the system, so when they hit the field, we don’t have any bugs to iron out,” Baker says. “Our service contract might not be as flashy as some, but it works well for us as a small, independent dealer. Our gross revenue was $90,000 in 2008, and this past year we had over $4 million in sales.”

Some customers were angry the first year Baker offered the service contracts because they didn’t realize what not having one would cost them. He’s since made sure to educate his customers on the drawbacks of proceeding without a contract.

“We have some small growers with 6-row planters that tell me they can bring me out for a service call and not have to spend $600,” Baker says. “That’s fine, but I make sure they understand that we charge $125 per hour and $2 per mile if they’re not on a service contract. We also charge per 15-minute phone call.”

Johnson Tractor, meanwhile, offers a couple options for phone support. Customers can get unlimited support throughout the year for $300 or choose to pay as they go. Every new piece of equipment also comes with 1 year of premium support.

Watch: Alleviating Service Stress During Busy Season

Watch Abby Weltzein, Joe Anderson and Chad Baker discuss their top strategies for preventing burnout and minimizing service stress at the 2024 Precision Farming Dealer Summit by clicking here!

“The premium support package allows us to schedule visits before the rush and helps customers avoid seasonal startup glitches,” Anderson says. “It includes a visit to their farm. We spend a couple hours with them getting set up and training them on how to run the tractor or combine to the point where they’re comfortable operating it on their own.”

At the end of the day, Anderson says the goal should always be to control your stress, and no matter how hectic it gets, make sure the stress doesn’t come home with you. The combination of customer clinics, training and service agreements has proven to be a solid formula for alleviating service stress during the busiest months of the year.

“We serviced 321 units in 2023. Our average technician workweek was 73 hours over 6 weeks, 27 hours less than it was in 2022,” Weltzien says. “That’s almost 30 hours back in their pockets that they’re spending with family at home not thinking about work.”