TREMONT, Ill. — Precision Planting revealed projects focused on improving the operation and data collection of sprayers at its annual Winter Conference on Jan. 18. This announcement marks the company’s first move into sprayer technology.

“Precision Planting is for farmers who believe in better, and nowhere is that more apparent than at the annual Winter Conference,” said Bryce Baker, marketing manager at Precision Planting. “With today’s sprayer announcements, Precision Planting expands our focus of challenging the status quo into crop sprayers, along with existing lines for planters, combines, seeders and sidedress bars.”

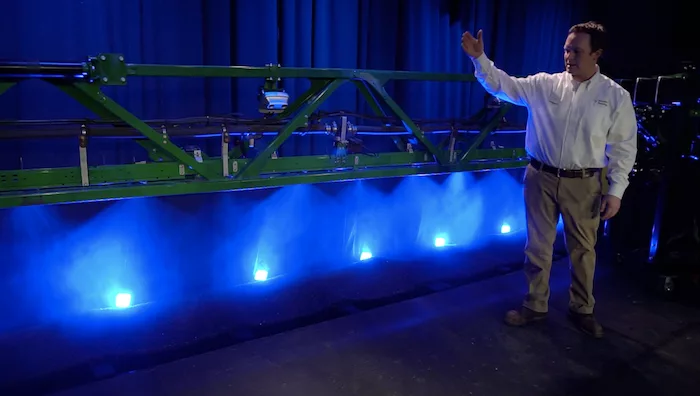

ReClaim Boom Priming and Recirculation

Traditional sprayers require farmers or operators to spray product to the ground to prime the width of the boom fully. Many times, more than 50 gallons of product is sprayed, causing a hot spot of chemicals. With ReClaim added to sprayers, chemicals mixed in the tank can be circulated through the booms and back to the tank, never having to spray a drop of chemical to the ground.

Traditional sprayers require farmers or operators to spray product to the ground to prime the width of the boom fully. Many times, more than 50 gallons of product is sprayed, causing a hot spot of chemicals. With ReClaim added to sprayers, chemicals mixed in the tank can be circulated through the booms and back to the tank, never having to spray a drop of chemical to the ground.

“ReClaim uses a single rocker switch in the cab to engage recirculation, and once recirculation is completed, farmers are ready to spray with the correctly mixed chemical across the entire boom,” said Justin McMenamy, director of product, Precision Planting. “ReClaim is designed to be retrofit onto a farmer’s existing sprayer with electric or standard nozzles.”

Symphony Nozzle Control System

Many sprayer nozzles have a change in pressure when sprayer operating speed or rate are changed. This change in pressure changes droplet sizes, increasing the risk of drift or reducing leaf coverage of the spray, resulting in reduced efficacy. The Symphony nozzle control system allows the sprayer to maintain constant pressure even when changing rates or speed.

Many sprayer nozzles have a change in pressure when sprayer operating speed or rate are changed. This change in pressure changes droplet sizes, increasing the risk of drift or reducing leaf coverage of the spray, resulting in reduced efficacy. The Symphony nozzle control system allows the sprayer to maintain constant pressure even when changing rates or speed.

“When spraying to kill weeds or diseases, it is important to get consistent spray patterns across the field, even when changing speeds or rates,” said Luke Stuber, Symphony product manager at Precision Planting. “Symphony maintains consistent pressure across the boom, along with swath control and turn compensation for consistent spray coverage across every acre of the field.”

Controlled by the Precision Planting Gen3 20|20 system, Symphony will be field tested again in the spring of 2022.

Vision-Based Technologies

Precision Planting announced multiple applications of cameras on a sprayer, all being developed by the Precision Planting Research and Development team. The vision technologies will pair with the 20|20 Gen 3 system and will be further field-tested in the spring of 2022:

- Vision-Based Guidance: Post spraying crops is a high-fatigue job on the farm, often with the operator hand driving the sprayer to keep from running over crops. Vision guidance steers the sprayer in the crop rows, allowing the operator to focus on sprayer operations and not on steering, all while preventing running over crops and providing a significant reduction in operator fatigue.

- Vision Scouting: One of the best times to check for even crop emergence and stand counts is when most farmers make a post-emergence spray pass. Vision-based scouting will provide farmers with a snapshot of their stand count in the field and information about how evenly the crops emerged, letting them know if there are areas of the field to which they should pay more attention.

- Vision-Based Weed ID: Vision-based weed ID uses machine learning and artificial intelligence to see and categorize each plant seen in the field as a crop, a broadleaf weed, or a grass weed. With this information, a map of weed pressure can be created that allows farmers to understand the type of weeds and the variability in pressure across the field.

- Targeted spraying technology: Precision Planting’s Symphony Nozzle control system is being designed to pair with the Precision Planting vision module for targeted spraying.

“The combination of vision and Symphony will allow spray rates to be varied within the label rate to be effective against the weed pressure in a specific area,” said Jason Stoller, Vision product manager at Precision Planting. “We know that a high percentage of sprayer passes use a residual herbicide, so targeting only growing weeds does not allow for the value of the residual herbicide to be present in the field. We are actively researching the best way to spot spray growing weeds while at the same time laying down a blanket residual herbicide in order to control emerging weeds, all using the 20|20, Symphony and Vision technologies.”