A no-tiller since 1978, Bill Lehmkuhl saw the need for local crop consulting when he returned to his family farm after graduating from the Ohio State Univ.

“There was nobody in the area, including retailers, who were doing site-specific agronomy work at the time,” Lehmkuhl recalls. “I built my own rig with a GPS and computer on it, and that’s how I got started.”

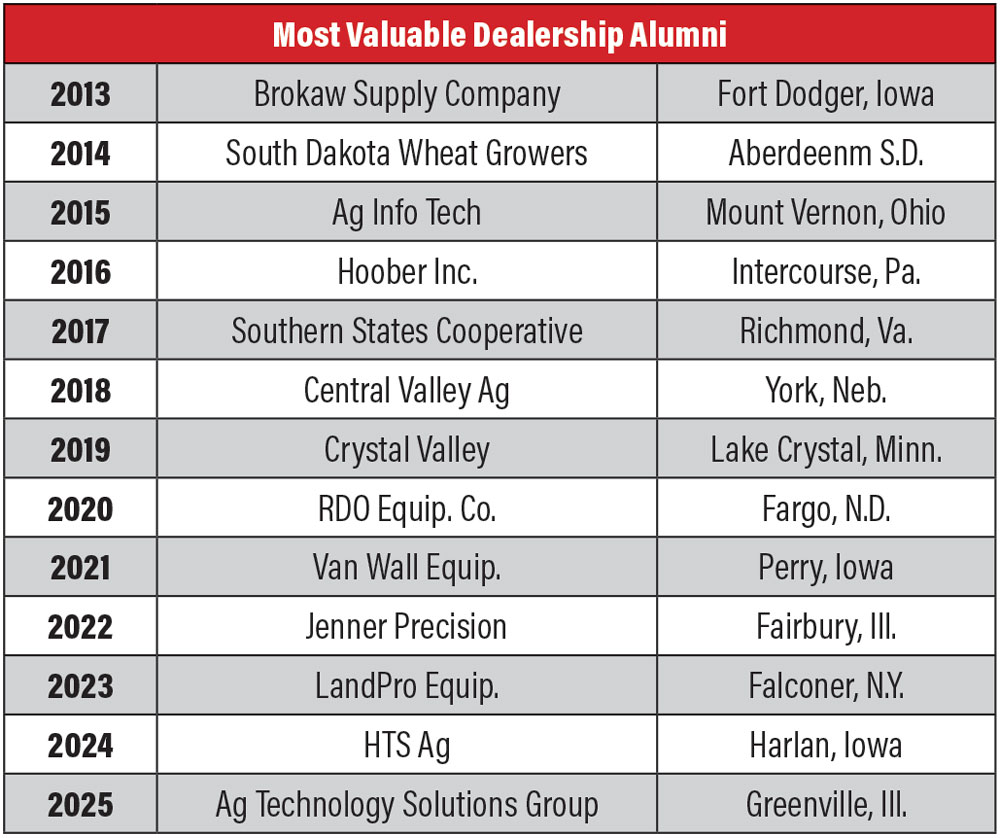

Lehmkuhl launched his independent crop consulting business in 1994, a business that eventually became Precision Agri Services Inc. (PASI), Precision Farming Dealer’s 14th annual Most Valuable Dealership.

Check The Specs...

Founded: 1994

Locations: 2

Employees Dedicated to Precision Farming: 13

Precision Lines Carried: PTx Trimble/Precision Planting, Ag Leader

Equipment Brands Carried: Horsch, Harvest International, LDM, Yetter, Wearparts, 360 Yield Center (360 RAIN), SurePoint Ag Systems, GBGI, Martin-Till, Copperhead Ag

Total Precision Revenue: $2.1 million

Precision Service Hours Billed: 1,017

Today, the Minster, Ohio-based dealership offers planter, technology, data management, crop consulting and agronomy services to customers in Ohio, Indiana and Michigan.

Lehmkuhl and his team of 13 — which includes 3 full-time agronomists — need to clear some space in the trophy case because they also received the 2025 Top Volume award from Precision Planting for being the company’s top seller in the region.

During a challenging year in the ag industry, PASI relied on its two core principles to separate itself from the pack: elite service and hands-on education.

Precision Origin Story

Shortly after launching his crop consulting business, Lehmkuhl remembers a good friend telling him, “You need to talk to this Gregg Sauder (Precision Planting founder) guy.” The rest is history.

“I became a Precision Planting dealer in 1996,” Lehkmuhl says. “People were always coming to us with questions about planter setup and that’s how we got started.”

From there, PASI evolved into a multifaceted operation, offering planter and technology products and services on top of independent, unbiased crop consulting and agronomy services.

PASI prioritizes hands-on training and education during its field days, which take place next to the shop at the company’s headquarters in Minster, Ohio. PASI

Agronomy lead Matt Vehorn manages the crop consulting side of the business, while Justin Goubeaux, COO and vice president of sales, leads the planter and technology side. Lehmkuhl oversees both departments as president and CEO. His wife Carol, who joined the team in 2011 while finishing up a 31-year career with Honda, fills multiple roles as the resident Swiss Army Knife.

“All of our specialists and technicians also serve as salespeople,” Lehkmuhl says. “While everyone has their own specialty area, we cross train to make sure everyone knows the entire product line and can support our customers. The entire team depends on the internal support staff as well, which includes the office manager, parts and inventory manager and internal operations manager.”

The Little Things

When Precision Farming Dealer visited PASI headquarters right before Christmas, members of the agronomy team were hard at work in the climate-controlled warehouse putting together gift baskets for agronomy customers.

“We’ll take the baskets to our customers and discuss if there’s anything they need from us,” Lehmkuhl says. “Some of the agronomy customers are also planter and tech customers, so there’s some crossover there as well.”

Honoring North America's Top Precision Dealer

Precision Agri Services Inc. (PASI) was presented with PFD’s 2026 Most Valuable Dealership plaque at the Precision Farming Dealer Summit in St. Louis. PASI is the first Ohio dealer to receive the award since 2015 (Ag Info Tech, Mount Vernon, Ohio).

Dealerships of all sizes and types across the U.S. were nominated by their customers, suppliers and employees.

Evaluated criteria for the award included precision farming sales growth and diversity, along with how each nominee generates revenue from hardware, software and precision service. Other elements such as employee training, performance standards, innovation, sustainability and community involvement were also considered.

Gift baskets might seem insignificant to some, but those little things add up over time and symbolize the family-like atmosphere at PASI that people love.

“If you stick to your fundamental roots of business, then you can be around for a long time and continue to grow,” says Goubeaux, who joined the dealership as employee No. 4 in 2012. “We don’t ever want to lose our family-owned aspect.”

PASI employees — 95% of whom are farmers themselves — go the extra mile to build credibility and trust. They also think outside the box, whether it’s using a new 3-D printer to build module brackets, doing liquid work on a custom-built containment table in the shop cleaning room, or hosting interactive field days for customers and non-customers right outside the shop.

Interactive Learning

“Education is a big part of what we do here,” says Lehmkuhl, who’s conducted planter clinics in over 22 states and across Canada throughout his career. “When you come to our field day, you’re going to get dirty. You’re digging seed, pulling plants, digging behind the planter, the whole 9 yards.”

The field days have morning, afternoon and evening sessions, with an average attendance of 100-plus for each.

Meanwhile, the 36-person conference room on the second floor of PASI headquarters serves as an on-site training center for staff and customers. A 98-inch touchscreen Smart Board allows for hands-on customer clinics and educational sessions.

Lehmkuhl showcases the spacious PASI warehouse. “When we designed it, we went up high,” Lehmkuhl says. “We have a reach truck that can go clear to the top.” Customers can also pick up parts after hours in a room that’s monitored by cameras and requires an access code to enter. Noah Newman

“Some OEMs say we’re shooting ourselves in the foot by teaching people so much,” Lehmkuhl says. “Our goal is to give them basic knowledge to troubleshoot on their own before they pick up the phone and call us. It saves us time and saves them a service call.”

Lehmkuhl says they don’t currently have any service plans, but with the emergence of remote support capabilities, they’re likely going to develop some packages soon.

“In the past, it’s been if you come to monitor training here, then we’ll give you a discount on service calls. If you don’t, you’ll get charged full price.”

Trustworthy Consulting

Last year was a mixed bag for PASI customers, especially those who farm in the drought-stricken areas of northwest Ohio.

“There was a drought from our location north,” Lehmkuhl says. “It was one of the driest spots in North America. We didn’t get any rain after August 1. It hurt corn yields. But some of our locations to the south had good yields. So, it pays to have a customer base that’s spread out.”

Even with low commodity prices impacting equipment sales, Lehmkuhl says customers are still spending money on retrofit technology for their planters and sprayers.

“Education is a big part of what we do here. When you come to our field day, you’re going to get dirty…”

“That’s where the education part factors in. We explain what poor emergence is costing them and what the biggest ROI is on the next great tech for planters and sprayers,” Lehmkuhl says. “Farmers put their trust in you when you’re not just selling them something to sell them something. You’re trying to help them improve.”

“The way we approach sales is as a consultant,” Goubeaux adds. “We’re consultants to the farmers.”

Goubeaux usually spends up to 2 hours on the phone or in person with new customers who are interested in buying a product, leaving no stone unturned in the pursuit for practical solutions. They often end up buying something completely different than intended.

Behind the Scenes at PASI

Head to PrecisionFarmingDealer.com/MVD to watch the 10-part video series on Precision Farming Dealer’s visit to PASI headquarters in Minster, Ohio. The series includes a tour of the shop, showroom, warehouse and more, as well as interviews with Lehmkuhl and Goubeaux about on-farm agronomy trials, customer clinics, finding success in challenging times, sales strategies, new technology, recruiting, cross training, 3-D printers and more!

“Everybody has the ability to sell, we continue to push the consultant approach,” Goubeaux says. “Ask the right questions. There’s no dumb question. Just because a guy calls and says he wants something, a lot of times it’s not actually what he needs. By the time you look at their whole operation and ask the right questions, you end up pointing them in the right direction. I don’t have to make a sale every time to that customer to make them our customer.”

The crop consulting side of the business didn’t skip a beat in 2025 as farmers focused on improving their efficiency and profitability. PASI agronomists sampled over 50,000 acres in the fall and have covered over 142,000 total acres to date.

“The agronomy side certainly helps in times like these, balancing things out cash-flow wise,” Lehmkuhl says. “Customers are looking at us and saying, ‘Can I get by a year without spending money on expensive inputs?’”

Selling Iron

An agronomist at heart, Lehmkuhl was hesitant to become a “major iron dealer,” but that changed recently when PASI started selling Horsch planters, seeders and tillage equipment.

“It’s been good. It has its niche,” Lehmkuhl says. “Here in Ohio, with the Lake Erie Watershed and some of the water quality programs, the seeders have been big for cover crops and soybeans.”

Horsch is family-owned and operated, so its values and culture are a good match for PASI. Goubeaux led the charge on sealing the deal with Horsch, but it didn’t happen overnight.

Carol Lehmkuhl, who worked for Honda for 31 years, joined the PASI team in 2011. She’s filled multiple roles over the past 15 years and currently helps wherever needed by delivering parts, pulling jobs, greeting customers in the showroom and more. Noah Newman

“We said no to Horsch for 3 years before we said yes,” Goubeaux says. “It was because what they offered on their planter didn’t match up with anything we were doing. What we offered on individual control for planters, we thought was better for our customers.

“Then Horsch signed a contract with Precision Planting. The day that was released, their rep showed up at our door. My answer before was their equipment and ours didn’t align, but now I needed to reconsider that.”

Goubeaux and technician Kurt Flaute followed up with a visit to the Horsch factory in Mapleton, N.D.

“I told them, ‘I want some wrenches and a row unit, and leave us alone.’ They gave us a row unit. We tore it apart and looked at all the parts,” Goubeaux says. “We decided it was a very robust piece of equipment and would be a complement to our business.

“Our goal is to sell a couple planters a year,” he adds. “Horsch’s goal might be different, but we understand what we can do and handle as a business. We will never be your big-time iron dealer, and we don’t want to be.”

Goubeaux’s team accomplished its goal in 2025, selling multiple Horsch planters and seeders, each retrofitted with Precision Planting technology.

Bleeding Edge

While Goubeaux guided the Horsch venture, Lehmkuhl spearhead the dealership’s addition of 360 RAIN — an autonomous irrigation, manure and nutrient application machine — from Sauder’s 360 Yield Center. Lehmkuhl was right there on the ground floor with 360 RAIN, just like he was with Precision Planting 30 years ago.

“Justin and I looked at 360 RAIN when it was in its infancy 4 years ago,” Lehmkuhl says. “We took a couple farmers with us to check it out, and they said it could be a major difference-maker.”

The machine has proven to be a good fit for PASI customers, especially those in the livestock belt who are constantly looking for new ways to apply manure. There were 15 360 RAIN units running on customers’ fields in 2025. Lehmkuhl plans to hire a 360 RAIN product manager soon.

PASI has made a name for itself by being on the bleeding-edge since 1996 and that trend continues with its addition of the PTx Trimble OutRun autonomous grain cart kit. Lehmkuhl’s team started testing it out in 2025.

“We might try to do some testing of autonomous seeding with it as well,” Lehmkuhl says. “We had a good experience with OutRun. There were some glitches, but nothing major that can’t be worked through. We’re happy and pleased with it overall.

“I had experience with the systems from Raven and Smart Ag because we were originally a Smart Ag dealer. Things have come a long way as far as the ease of installation, and the functionality of the user interface will continue to grow. It’s a viable system for those who don’t have enough help in the fall on the grain cart side of things. Autonomy of some sort will continue to grow in the ag industry.”

Looking Ahead

Lehmkuhl was reminded in 2025 more than ever about the importance of maintaining good relationships with vendors and OEMs. In his early years, he didn’t want to go down the road of working with OEMs because they were often perceived as “the enemy,” but that philosophy changed over time and has paid off for PASI.

“No matter what you think, it’s very important to keep in contact with your vendors, know what they’re thinking and vice versa,” Lehmkuhl says. “The relationships we’ve built with OEMs have worked out very well.

PASI Customer Testimonials

“I knew you knew what you were doing within 30 seconds. I have no patience, and I know if I call, I will get an answer. Product knowledge and service is everything.” — Steve Hines

“Evan Aufderhaar with PASI has been great to work with. Everything he told me, he followed through on in a very timely response. PASI’s product knowledge and support have been great.” — Chad Tyron

“Support has never been an issue. I was able to increase efficiency on the farm without adding more operators.” — Anthony Schroeder

“We have a great working relationship with Deere, Case IH and AGCO dealers in the area,” he adds. “We provide training for an AGCO dealer. Their techs have our support line and all our personal numbers. Never be afraid to cultivate those relationships with OEMs, that’s the advice I’d give to others.”

Heading into 2026, PASI is well positioned to build off its award-winning year and improve on its $2.1 million precision revenue total from 2025.

“This past year had its challenges as everyone in the industry is aware,” Goubeaux says. “I farm. I get it. I’m looking at my books and realizing I don’t have a ton of money to spend.

“But we’re still here. Guys are still calling. We’re still doing the little things that make a difference,” he adds. “When the markets turn around, technology sales will pick up even more and we’ll be here for it.”