There are 5 levels of autonomy generally accepted within automotive and off-road equipment engineering circles. The highest level is reached when a machine operates with full autonomy, going anywhere and doing anything an experienced human operator can currently achieve.

“People ask me when we’ll see Level 5 automation in agriculture,” Sabanto founder and CEO Craig Rupp says. “I tell them, we’re doing it now.”

Sabanto started building its first autonomy kit in late 2019. Now, after closing on a $17 million series A funding round in August 2022, the swarming farm autonomy company has accelerated the process of bringing its product to the marketplace.

What does it take for a small startup company to reach the highest level of autonomy in such a short amount of time? We reached out to Rupp and set up a meeting with his top employee to find out.

4:00 a.m.

It’s the Friday before Thanksgiving and I’m wide awake 3 hours earlier than usual, preparing to make the 5.5 hour drive from Brookfield, Wis., to Ames, Iowa, for our Day in the Cab visit with Sabanto Vice President of Product Cory Spaetti.

Once the first cup of coffee kicks in, it’s hard to contain my nervous excitement for the day, not only because it’s my first big assignment as a Precision Farming Dealer editor (no pressure!), but it’s a rare opportunity to go inside the company our sources have been telling us to “keep an eye on” for quite some time.

7:15 a.m.

About halfway through the drive I stop at an exit for my second cup of coffee. I pull up Sabanto’s website on my phone for some last-minute research while waiting in the drive-thru line. Other than a 17-word mission statement and a team roster with a brief quote listed under each person’s name (“AARR, I’m a pirate” pops up when you drag the cursor over CEO Craig Rupp), there isn’t a whole lot of information to be found, adding even more intrigue to the adventure ahead.

10:30 a.m.

I make it to the Sabanto offices right on time, still energized from that second cup of coffee. The jovial Spaetti opens the door and greets me like a longtime friend, even though it’s the first time we’ve met. I feel right at home almost immediately as we head inside the building.

10:34 a.m.

Walking into his office, Spaetti informs me he just got back from a road trip of his own. He and a Sabanto engineer visited a supplier in Des Moines to investigate “whether they can do more for us.”

As they prepare to commercialize their product, the Sabanto team uses post-it notes to map out the customer journey, from pre-sales all the way to renewals and expansion.

“The struggle has been finding suppliers that fit our needs,” Spaetti says. “Every day I wake up to an inbox full of messages basically saying, ‘We’re this company and we can do this for you.’ We have to hedge our bets. We’ll try and then we’ll trust. For example, we might order a couple parts from different companies and see who can make it the best.”

I ask him if Sabanto has dealt with any significant supply chain issues in 2022. His answer is yes, unsurprisingly.

“We’ve had some connectors on order since August 2021, and it’s just now finally getting to the point where they’re almost going into production,” Spaetti says.

10:40 a.m.

Our conversation shifts to a more personal tone as we learn about each other’s background. Spaetti’s face lights up when talking about his 3 kids (4, 6 and 8 years old). He also talks about the challenges of being a “maker” in a managerial position.

“The hard part of being a ‘maker’ in this position is stepping back and realizing that everyone around me is my responsibility,” Spaetti says. “Do they have their marching orders? And those can change at the drop of a hat. It’s a wild ride, but it’s part of what gets me out of bed every day.

“A lot of us come from big companies and we left because we couldn’t be makers there,” he says. “If a week goes by where all I do is sit behind this desk, I get a little antsy.”

Spaetti shares his origin story with the company. He started working at Sabanto in fall 2019 after stints with CNH Industrial and Kubota. Before that, he was a corn, soybean and wheat farmer from Southern Indiana.

“I enjoyed my time working for several different larger companies. But there were many days when I thought, ‘Why am I doing this and why am I doing that?’ Here at Sabanto, all those experiences in the past have come together in the present. I know how to order parts. I know how to work with farmers. I know how to work with engineers. I know how to speak with investors. You have to be a Swiss army knife to work in a small company like this. I’m having a good time here. I love my co-workers and teaching young folks that come into the company how to handle challenges.”

Sabanto Releases First Autonomous Kubota M5 Tractors

Not too long after our visit with Cory Spaetti, Sabanto officially announced the availability of its autonomy kit for Kubota M5 tractors in North America.

“We are completely disrupting the way the industry views autonomous equipment, and we are bringing in partners who share our vision,” says Craig Rupp, founder and CEO of Sabanto. “We see a future of smaller, smarter, lighter, less expensive and more sustainable swarms of autonomous equipment that will enable users to cover more ground with less.”

10:55 a.m.

Now it’s down to business. Spaetti logs into his computer and brings me up to speed on what Sabanto is all about. He tilts his monitor toward me, sharing pictures of his journey with the company, starting with the early days in his 3-car home garage.

“Craig (Rupp) wanted to use these smaller Kubota tractors,” Spaetti says. “My job was to get the tractor ready for the electrical and software guys. I was stripping parts piece by piece. Not glorious by any means.

“We had a small office in downtown Chicago, but for the most part we spent our time working on folding tables in my garage trying to figure stuff out,” he says.

11:00 a.m.

Spaetti plays a video of the maiden voyage when they attempted to plant autonomously with a small tractor in a 400-acre field in Chatham, Ill., in November 2019.

“It was called the sludge field,” he says. “When they scraped the bottom of Lake Springfield all the sludge ended up in this field. I was thinking, ‘Oh this will be great.’

“The tractor is navigating on its own for the first time and I’m riding on it as it’s planting,” Spaetti says while the video plays. “Everything went completely haywire the next day. It was a nightmare. The ground got too wet, and we just couldn’t pull the drill through the soil. We ended up punting but looking back, it’s amazing we were able to take that first big step as quickly as we did.”

11:15 a.m.

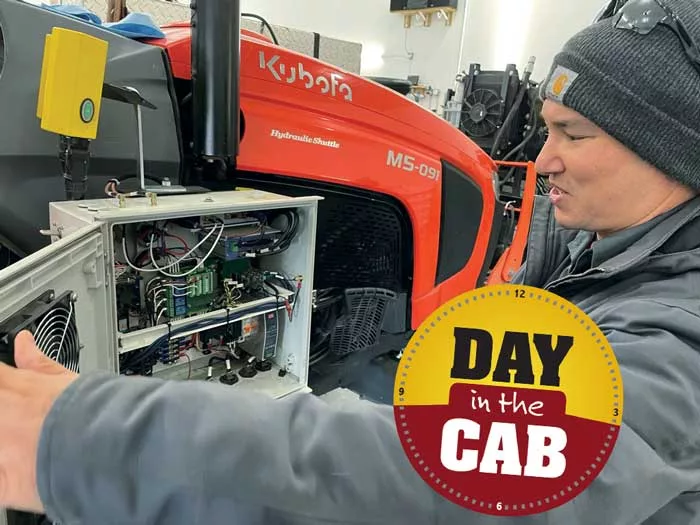

Spaetti continues to scroll through hundreds of photos and videos. He eventually stops on a picture of an electronic box with wires that looks like something you’d see on a MacGyver episode.

“We had this wreck of a control box (autonomy controller) with a lot of reliability issues,” he says. “We hired an electronic technician to help us out. All we did in the summer of 2020 is work on that control box in my garage. We really improved our reliability by the end of July.”

From the garage to the field, it didn’t take long for Sabanto to make a good first impression with its technology and secure opportunities with new clients.

Since its inception, Sabanto has autonomously tilled, planted, seeded, weeded and mowed fields in Illinois, Iowa, Indiana, Missouri, Nebraska, Minnesota, North Dakota, Wisconsin and Texas with a fleet of smaller 60 and 90 horsepower tractors.

11:20 a.m.

Spaetti shares the story behind a pivotal moment in the young history of the company, when their work caught the attention of Scott Air Force Base in St. Clair County, Ill.

“They discovered us on Twitter,” he says. “They noticed us autonomously planting with Kubota tractors, which they use on their base for mowing. We did a demonstration for them in May 2021, and it went really well. In September of that year, we inked a 5-phase contract to mow their fields using our autonomous technology. Everything we built for them we wanted to be able to use in agriculture.”

11:35 a.m.

Spaetti pulls up the Sabanto mission control site on his computer. He shows how an operator, with the click of a mouse, can control their autonomous tractors from anywhere in the world. He walks me through the process of building a mission plan with the program.

“When I create a mission I can pick the job type, the coverage plan, and I can also select which vehicle I want it assigned to,” Spaetti says. “If I have multiple vehicles assigned to a job, I can specify which passes I want each machine to execute. We try to make this as easy as possible. I can remotely control the machine, start the engine, raise and unfold it and so on.”

Check Out the Day In the Cab Video Series

Visit www.precisionfarmingdealer.com/ditc to watch exclusive, behind-the-scenes footage from the Sabanto offices in Ames, Iowa. Vice President of Product Cory Spaetti expands on how the company’s autonomy system works and what it takes to bring it to the marketplace.

He loads a plan for a Fendt tractor equipped with the Sabanto autonomy system. It’s located on a field adjacent to Sabanto’s workshop in the nearby town of Nevada, which Spaetti tells me we’re going to check out in a little bit.

“We spent quite a bit of time this year automating this Fendt tractor that belongs to a biofuel company called Verbio,” he says. “A lot of what we learned from automating the Kubotas we then carried into automating this larger, more modern tractor. This is where we start to make a dent in acres per day and hour. We’re talking 10-12 acres per hour vs. 5 acres per hour.”

11:50 a.m.

It’s time to leave the office and head to the workshop. Before we go, Spaetti gives me a tour of the building. It’s fairly quiet on this Friday morning. Most of the team is on the road or working at the shop.

We stop by the conference room. A framed front-page article on Sabanto from the Des Moines Sunday Register hangs on the wall. The headline text reads, “Self-driving vehicles could save on labor. Iowa startup hopes to revolutionize farming with ‘swarm’ of small, autonomous tractors.”

As we make our way back through the main work area Spaetti talks about his growing team of engineers.

“We’ve had 10-plus people join the company over the last few months,” he says. “I’ve had all these designs and projects that I never had time to work on. Now, suddenly, I have a small army that’s very capable. It’s my job to stay out in front and keep feeding them projects.”

11:55 a.m.

Some of the newest Sabanto team members are recent college graduates. Spaetti shows me the desks of Adam, Cody and Logan, 3 engineers from the hometown school – Iowa State University.

“Nothing makes me happier than seeing a young person take on a challenge and figure stuff out. What we do every day is really hard because we’re trying to take this square peg and fit it into a round hole. We’re taking an autonomous tractor that’s smaller than anything a current farmer uses and making it fit into their pre-existing system.”

A giant white board with a bunch of multi-colored post-it notes catches my eye. The notes are organized in columns under the following categories: pre-sales, sales, onboarding, learning, product usage, support, renewals, and expansion. Spaetti explains how the board essentially maps out the customer experience.

As the tractor comes to a stop, Cory Spaetti takes control by switching from autonomy to manual mode.

“As we get closer to commercializing our product, we have to think deeply about what our customer journey looks like,” he says. “There are software and tools you can spend a lot of money on to do that. But we figured why not just do it with post-it notes. If someone thinks of something in the middle of the night, they can write it down and slap it on the board. Then we’ll figure out where it fits and how to prioritize it.”

We eventually exit the office building, hop in our cars and head to the workshop. It’s time to see autonomy in action.

12:15 p.m.

I spot the autonomous Fendt tractor off in the distance on a snow-covered field as we pull up to the Sabanto workshop. We head inside and Spaetti introduces me to his dream team of engineers, Logan, Adam, Vlad, Cody and Evan, all hard at work on various projects.

12:20 p.m.

Spaetti opens up the mobile version of the mission control site on his phone and starts the Fendt tractor.

“It’s moving along at about 4.5 mph,” he says, while pointing at the tractor located a few hundred feet away from us. “We’ve got it set to go a little slower today because of the snowy conditions.

“It’s a lot of fun to watch the cars go by and see people stop and take notice of a driverless tractor running in the field.”

12:25 p.m.

We walk up to the tractor. Spaetti stops it so we can climb inside the cab. Once we’re in, he restarts it with his phone and off we go.

“These autonomous operating systems make great offices for getting a lot of work done,” Spaetti says, as the tractor moves along, following its mission. “I’m guilty of working on my laptop in the cab as the tractor does its thing.

“I don’t think we’re in a place where the human can be taken completely out of the loop. But I will say that the technology coming to the marketplace will make it easier for an operator to command multiple machines and get a lot of work done in a day.”

I pepper Spaetti with questions as the tractor continues to follow its path. The first one is about the company’s Farming-as-a-Service (FaaS) business model. He tells me they’re pivoting from FaaS and focusing more on improving their cutting-edge technology.

“FaaS gave us the opportunity to take our equipment into farmers’ fields and perform operations,” Spaetti says. “But we discovered that we were taking one person’s labor problem and piling it on top of our own. It stretched us a bit thin and taught us if we could do anything good for the farmer, we needed to figure out how to make our technology simple to use, cost effective and robust. We’ve taken the stance that perhaps we can be a technology provider to enable others to provide FaaS.”

My next question: “Where do you see Sabanto 10 years from now?”

“If there was a world where we could turn this into a sustainable, standalone business, that’s the world I want to live in mainly because I like working in a small company,” Spaetti says. “The other way it could go, which I believe our shareholders would probably rather see, is the potential for an acquisition by another big fish out there. But I feel if we just do our jobs right then everything will take care of itself.”

12:45 p.m.

About 20 minutes into the ride the tractor comes to an unplanned, abrupt stop.

“So, this is very common, just an example of the bugs we’re working out right now,” Spaetti explains. “It’s part of the development process. We’re going to turn everything off and restart the tractor.”

It turns out to be perfect timing. Spaetti’s phone rings and he quickly answers it. A parts supplier is on the other line.

He hangs up after a couple minutes, restarts the tractor and we’re off and running again.

12:55 p.m.

After completing the mission plan, Spaetti changes the tractor from autonomy to manual mode with the flip of a switch. He drives it back to the workshop where we wrap things up with a couple short videos, the first of which showcases the nuts and bolts of Sabanto’s autonomy kit.

“At the heart of our system is a single autonomy controller,” Spaetti says. “The onboard autonomy controller receives mission plans from our cloud infrastructure and spits out all the commands to the tractor. Some of the additional componentry we add to the vehicle would include a steering valve, an electrohydraulic remote valve, GPS receiver, obstacle detection cameras and 2 LTE antennas.”

1:10 p.m.

As we finish the video shoot, I compliment Spaetti on his broadcasting skills. Most people we interview aren’t as comfortable and tend to tighten up once the camera turns on.

“You’re a pro at this,” I say. “You should have your own show!”

“Well, I do this about twice a week,” Spaetti says with a laugh. “We had a candidate dealer meeting here the other day. I was basically doing the same presentation for them.”

We head back out to the parking lot, preparing to go our separate ways. Spaetti recommends a coffee shop for me to visit before I hit the highway. We say our goodbyes. He’s off to see a local parts supplier and I’m off to fuel up on more caffeine for my non-autonomous drive back home.