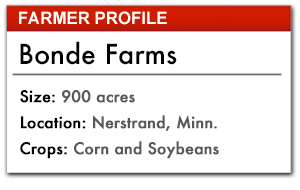

Nate Bonde farms with his two cousins, Gary and John Bonde near Nerstrand Minn. They’ve been increasingly using precision farming practices in their operation since 2008 when they switched from ridge-till for corn production to strip-till.

“When we made the switch, we fought with the old ridges,” Bonde recalls. Seeking a solution, they started with an Ag Leader Insight unit using only a Wide Area Augmentation System (WAAS) correction signal, but soon found they needed an RTK signal for better repeatability and accuracy.

Today, they use three Trimble FMX controllers for steering and recording in-field information. Their AGCO RT150 and DT250B tractors are outfitted with controllers with NAV II controllers that use an unlocked RTK signal.

Their Rogator 854 sprayer with 90 foot boom and five-section shutoff has a FMX unit that follows a WAAS signal. They are also setting up the sprayer with a 60 foot, three-section boom to variable-rate sidedress 28% nitrogen with Y-drop nozzles.

“We use a Yield 360 SoilScan unit to identify available nitrogen in the soil, then adjust rates accordingly,” Bonde says. “We started on 4-acre grids, but will probably look at 10-acre grids this year. We use our four-wheeler to pull samples and it takes about 3 minutes to process one sample.

They build their strips in the spring with a DMI 2500 6-row no-till deep-shank ripper that’s followed by a twin-bin Montag cart that delivers variable-rate potassium and phosphorous based on soil test results “We use Trimble’s TrueGuide implement guidance system, on the strip-till unit for greater accuracy,” Bonde says. “We had to mount it on a 10 foot mast because the Montag unit is so tall, it interferes with satellite signals.”

Their planter is a 12-row Kinze 3200 that’s been upgraded with Tru Count air clutches and WaveVision seed sensors. Precision Planting’s FieldView Plus software controls row shutoffs and tracks row-by-row performance through a 20/20 monitor.

“The upgrade was simple, just new harnesses to hook up to the NAV 2 guidance and shut-offs,” Bonde says. “It allows me to watch planting progress from my iPad remotely. I can see if there’s a problem and it also allows me to better judge when to deliver seed to the field.”

Point of Pain: Dealer Drive Time

The greatest deciding factor on switching from Ag Leader equipment to Trimble precision equipment was the dealer locations and availability.

“When we first started using precision equipment in 2008, there weren’t many dealers,” Bonde says. “Our closest dealer was an hour away. Now, our dealer is one mile away and has the parts and service capabilities we need.

“We had one FMX unit go down last year, and they were able to get it repaired and back to us quickly, we didn’t lose any time in the field,” Bonde recalls.

Future precision plans include upgrading the planter so they can vary planting rates. “The way we’re set up now, we can’t do test plots very easily,” Bonde says. “We’re trying to pencil it out to see if it’s worth to make the switch.”