Above photo: Patience and ingenuity are qualities Mike Houghtaling, president of P&C Ag Solutions in Reese, Mich., relies on to keep customers up and running, especially during spring planting.

Having shadowed several precision farming specialists from multi-store farm equipment dealerships for this series, I’ve come to appreciate the layered responsibilities that come with selling and supporting the technology of a major agricultural brand.

But for this installment, I wanted to experience how an independent precision dealer navigates the landmines and celebrates the successes of an anything by typical workday on the cusp of planting season. So I made the 6 hour journey from southeastern Wisconsin to Reese, Mich., in mid-April where I rendezvoused with Mike Houghtaling, president of Precise & Concise Agricultural Solutions.

He informally launched the company in 2001, selling precision hardware out of his family’s 2,200-acre farm near Reese. “My original intent with starting the business was so I could buy stuff for my farm on the cheap because there was no precision dealer nearby at the time,” Mike says. In 2005, he incorporated the company and 2 years later, moved into the store’s current location, a modest office space in the center of town, bookended on the main road by John Deere and Case IH dealerships.

With plenty of local precision options today for customers, Mike and his 7-person staff distinguish themselves with a genuine commitment to answer the most remedial question or solve the simplest problem, even amid the spring chaos.

Day in the Cab Video Series

I also shot video along the way with Mike as the day unfolded. Click the button below to see a full series of videos from that day.

Day in the Cab Video Series

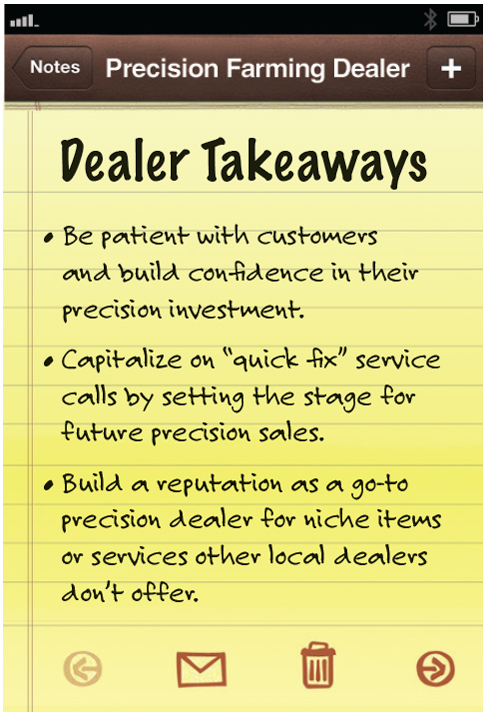

Whether it’s reassuring an operator that his planter airbags are working properly by hopping in the cab to make a field pass or surprising a farmer by dropping off a loaner guidance system so he can get back in the field, I had the opportunity to see how Mike’s casual and patient demeanor puts customers at ease, while building their confidence, even under the most stressful conditions.

6:05 a.m. Anticipating the abrupt sound of my cell phone alarm, I awake a little earlier than expected and silence the device. I spent the night at the Holiday Inn Express in Frankenmuth, Mich., a quaint tourist town about 20 minutes outside of Reese.

6:37 a.m. I devour a plate of sausage, a sweet roll and a banana and gulp down a glass of orange juice before grabbing a coffee for the road. Having touched base with Mike the night before, he plans to be at the store about 7 a.m. It’s already been a busy start to the week for him, having worked well into the evening the last few days. He’s hopeful that a moderate threat of rain today may provide a brief respite.

7:12 a.m. I spot P&C Ag Solutions’ sign from the road, sandwiched on the Sahr Plaza marquee among several other business that occupy office space in the building, including a crop insurance agency. I pull into the parking lot, park and enter the door with the company’s name and contact information printed on a piece of paper taped in the window.

The reception area is organized, but saturated with Post-It notes, paperwork and an array of different pieces of hardware. The radio is playing a Metallica song and I find Mike in the workshop rifling through parts drawers. He’s wearing a worn Detroit Tigers hat and company t-shirt.

7:20 a.m. Technically, the office doesn’t open until 8 a.m. and nobody else is here yet, which doesn’t surprise Mike considering they’ve been working a string of long days. He and four other precision specialists handle the bulk of service calls and have been running ragged getting customer’s planter systems ready to roll. He often likes coming in earlier to try and catch up on some administrative work, or as he calls it, “the calm before the storm.”

7:42 a.m. Mike gives me a tour of the office, which is a unique space, to say the least. The U-shaped desk unit in the main office is something that was custom built 2 years ago to accommodate Mike, his brother Dave, precision specialist Chris Hoffman and Gretchen Scramlin, the company’s administrator.

Ten computer monitors line the perimeter of the desk unit, and Mike says customers often tease him that it looks like some type of command center, which it does. “It serves its purpose and we’re all able to interact quite effectively,” he says. “We’re never all here at once, so we all have our own space, but we’ve definitely outgrown this place.”

7:51 a.m. We duck into the hallway behind the office where Mike checks a large whiteboard with customer names, parts numbers and notes. This is the dealership’s “secret scheduling area” where staff can meet each week to discuss which customers need the most attention to prioritize service calls.

Today, the board is full. This time of year, it’s constantly being updated as specialists erase completed jobs and add new ones. as needed.“We used to have this in the main office, but customers would always come in and stare at it, wondering ‘Where am I on this list’ or ‘I wonder what that other farmer ordered?’” Mike says.

Being an active farmer adds a layer of credibility to Houghtaling during sales visits, because he runs most of the precision equipment sold at the dealership. “Our customers trust us that if it’s good enough for my dad, uncle and me to run on our operation, it’s good enough for them.”

8:02 a.m. We head into the storage area where most inventory, parts and assorted electronic or mechanical widgets are housed. At first glance, the space resembles my own garage with storage tubs, garden hosing and sections of lumber scattered about. In spring, the dealership uses the space to test planter meters, but there are only a handful of units still on hand. Mike also stages and organizes customer orders in the warehouse, so specialists can pull a sales order, pick up the necessary parts in the morning and make deliveries in between service calls. There are a handful of orders spaced out on the floor waiting to be picked up this morning.

8:10 a.m. Mike grabs a can of Coke from the fridge in the warehouse and notes that the beverage is “the hallmark of our business.”

8:20 a.m. We hear some conversation in the front office as a few employees arrive. Mike takes visual stock of what is being worked on in the testing area in the front of the warehouse, where custom wiring harnesses are designed and built.

Although the work area looks like a “chaotic mess” this time of year, there is an underlying organization. A thick stack of three-ring binders contain sketches of all the different wiring configurations designed by the company. “This is our Holy Grail,” Mike says of the binders. “We’ve started to build a reputation that if anyone will have it, we will or we’ll build it.”

Sometimes, farm visits are just about boosting a customer’s confidence in a product, Houghtaling says. “Some guys don’t have the patience for these kinds of calls this time of year, but I don’t mind.”

8:33 a.m. Mike introduces me to Chris and precision specialist Calvin Morely, who have both been with the company for a few years. They check in with Mike and Gretchen about their schedule for the day and gather supplies and equipment before heading out. Mike checks the time and realizes we need to get on the road as well. “I told a customer I’d be at his place at 7:30 this morning and it’s now after 8:30.”

8:41 a.m. On the road to our first stop about 5 miles away, we make a quick detour to pick up a thumb drive that he left in the cab of his dad’s tractor last night after updating one of the displays. In addition to running a growing precision farming dealership, Mike is also intimately involved in his family’s farm. These split responsibilities pose logistical challenges this time of year, but being an active farmer adds a layer of credibility for Mike during sales visits.

“The equipment we sell is what we run on our farm,” he says. “Our customers trust us that if it’s good enough for my dad, uncle and me to run on our operation, it’s good enough for them.”

“The equipment we sell is what we run on our farm, so customers trust our expertise…”

9:02 a.m. After a sunny start to the day, clouds begin to roll in as we arrive at Terry Histed’s farm in Munger. We find him in the field, ready to plant, but he’s having an issue with his implement switch and getting his 16-row John Deere planter to turn on and off. Mike checks the connections on the planter and then hops into the tractor cab. He recalibrates one of the sensors and that does the trick.

After the quick fix, Mike takes a few minutes to talk with Terry about equipping his new 32-row planter with a Precision Planting 20/20 SeedSense monitor system in the coming year. We wrap up the visit and Terry thanks us and jokingly tells Mike, “I hope I don’t see you again today.”

9:12 a.m. We’re on our way to Don Rouech’s farm in Essexville. Mike uses the Siri function on his iPhone to try and call Don to let him know we’re en route, but the system calls another customer with a similar last name. We laugh that this is the second time this morning that Siri didn’t identify the right name, but Mike nevertheless says the voice activation function is a handy and reliable resource while on the road.

9:25 a.m. We arrive at Rouech Farms and Mike grabs a box from the back of his truck with a John Deere Computrac 250 planter monitor that he sold Don. Nobody is here, but we find Don’s Deere 8130 tractor and 12-row Deere planter in the shed so Mike hops into the tractor cab to install an update to the 20/20 monitor. Don arrives and it’s clear that he and Mike have a strong working relationship. They are casual and blunt with each other. They discuss area field conditions and Mike mentions that some farmers are planting today.

9:37 a.m. A first attempt at the 20/20 update fails and Mike tries it again. “Usually, this is a 5 minute deal,” he says. While we wait, Don asks us to come outside and tells Mike, “I’ve got something you’ll be interested in.” He shows us a recently acquired 3-point equipment caddy that he offers to sell Mike. The two negotiate a price and settle on $2,500, which includes payment for some pickle harvester parts Mike previously bought from Don. The two shake hands on the deal and I’m called on as a witness to the transaction.

9:55 a.m. With the 20/20 update completed, we finish up with Don and hit the road. Mike says it was a beneficial, if somewhat unusual stop. He certainly wasn’t planning on buying any equipment on the spot, but it was a piece that will be useful on his own farm or to transport tile plows from the dealership. “It was a good relationship-building visit,” Mike says. “I want to make customers feel like I care about them, because I genuinely do and value meeting with them and being a part of their operation.”

10:12 a.m. Our next stop is about 40 minutes away and we find a McDonald’s drive-thru for a late breakfast. Mike orders two sausage McMuffins and a large Coke with no ice. I get a coffee. Mike says he had a granola bar and a glass of orange juice before he left his house this morning, and this time of year, he eats when he can.

“Yesterday, it got to be 3 p.m. and it occurred to me that I hadn’t eaten lunch,” he says. “I probably get about 50 calls per day, but only live answer 10-15.” Texting is often the preferred method of contact for Mike, because he can quickly glance at a message and prioritize the request.

10:44 a.m. We arrive at Spartan Acres Farm in Freeland to meet Paul Knoerr, who isn’t here yet. Unlike our first two stops, Mike is less confident that this will be a simple solution. All he knows is that Paul is having trouble getting his 24-row John Deere planter configured. “We’ve done a lot of work on his planter in the past with some wiring issues, so this could either be a 1 minute fix or a few hours,” Mike says.

Paul’s Case IH Magnum tractor and planter are sitting at the edge of the field, but the cab is locked and Mike calls Chris Hoffman to see if he knows where to find the keys. In the meantime, Mike inspects the harnessing on the planter and everything appears connected.

11:02 a.m. We find the keys shortly before Paul pulls up. He and Mike hop into the tractor cab and boot up the display to run a diagnostics test, which reveals that none of the planter switches are showing up on the switch box. This is a problem Mike has seen before and a relatively simple fix. He tightens one of the Deutsch plugs into the auxiliary input module on the back of the tractor and the switches are back online.

“We’ve started to build a reputation that if anyone will have it, we will or we’ll build it…”

11:12 a.m. Paul runs a test of the planter drives from the cab, while Mike and I observe from the behind the planter. The drives don’t engage and Mike suspects an electrical problem. He grabs a few tools from his truck and plugs into the row unit with a meter to check the power. Satisfied with the output reading, Mike does some additional troubleshooting and determines the problem is with the hydraulics. He rechecks the connections and the drives re-engage after a few minutes. Mike gives Paul the thumbs up from behind the planter.

Both Mike and Paul are relieved that the job only took minutes, instead of hours. With the skies clearing a bit, Paul says he plans to cover as many acres as he can today. He and Mike briefly discuss possible upgrades for next year and the possibility of a new planter.

11:31 a.m. We part ways with Paul, but while we’re on the farm, Mike wants to check the base station of an onsite RTK tower that the dealership installed. We find the ground control panel and Mike opens it to make sure everything looks OK. “The biggest problem I find is either with rats or ants getting into these boxes,” he says.

Simple fixes are always appreciated and that was the case during a service call to Spartan Acres Farm and farm customer Paul Knoerr. This gave us unexpected flexibility to schedule more visits in the afternoon.

11:45 a.m. We are back on the road and heading to the store to check in. It’s been an unusually smooth morning and the efficient stop at Paul’s farm has given us some unexpected flexibility for the afternoon. Mike had budgeted a “worst-case scenario” of 2-3 hours for the visit, based on past experiences. “I checked his service history with us and I was mentally prepared for what we might encounter,” he says. “Luckily, it wasn’t that bad and we’re a few hours ahead of schedule.”

12:21 p.m. On our way back, Mike gets a call from Terry Histed, who we had visited earlier in the morning. He is in the field planting, but having problems with the sugarbeet population readout on his monitor. It’s showing 68,000 seeds per acre, when it should be showing 58,000. Mike knows where to find him in the field and says we’ll be there to check it out. Having grown up in Reese, Mike has longstanding relationships, both personal and professional, with many of his farm customers.

12:32 p.m. We meet Terry in the field and Mike hops into the tractor cab with him. After a couple planting passes, Mike is dropped off and we take a few more minutes to observe the planter in the field. Mike says the problem was an incorrect gear ratio on the seed meter, which needed to be corrected.

12:47 a.m. A few raindrops hit the windshield as we pull into the parking lot at the dealership. Almost everyone is either out or on the road. Carolyn Pepple, who helps design and build custom wiring harnesses, is in the back working on orders, and a couple of other part-time employees are working on other projects.

1:04 p.m. Mike logs onto his computer to update a few customer accounts. He uses Fishbowl to manage inventory and track purchase orders. He and the other specialists also log customer contacts in a program called Pipedrive. They can create or update entries after every service call or on-farm visit. Mike likes the system because it’s an effective, cost-efficient way to share equipment ideas for customers among the team.

1:37 p.m. Still in decent shape for the day, we take a lunch break and dine in at Track Side Bar & Grille, the local “hot spot” according to Mike. We both have the lunch special, a chicken club sandwich. A replay of the Tigers game from the night before is on TV, and we swap stories about the different ballparks we’ve visited and Mike shares a story of how he ended up on the David Letterman Show while visiting New York with his wife.

“I want to make customers feel like I care about them, because I genuinely do and value meeting with them and being a part of their operation…”

2:17 p.m. We briefly pop back into the dealership and are then on our way to AB Bierlein Farms in Richville. Mike had an earlier call from Brian Bierlein who is in the field planting sugarbeets and says his air bags are not adjusting properly. This type of call is relatively common, especially for customers who are newer to precision technology. “Sometimes, these visits are just about boosting a customers confidence in the product,” Mike says. “Some guys don’t have the patience for these kinds of calls this time of year, but I don’t mind because I want them to be satisfied with their purchase.”

2:34 p.m. Brian’s Deere tractor and 12-row planter are near the edge of the field when we pull up and Mike trots over to jump in the cab. They make a pass through the field and Mike is back in matter of minutes. His assessment is that the air bags are working fine, but because the terrain is so flat, there is minimal downpressure needed to adjust planting depth. He tells Brian that we will drive by in about an hour to make sure everything looks OK.

2:45 p.m. The afternoon is flying by and Mike is thrilled that we’re able to attend to as many customer needs as we have, so far. While problems have all been minor, they are the type that tend to be lower priority if more complex issues arise this time of year. “This is a luxury to have a day like this, but I’ll take it,” Mike says.

3:01 p.m. We arrive at our next stop, Zwerk & Sons Farms in Marlette. It’s an impressive operation and Mike says it’s one of the trend-setting family farms in the area. We’re here to check on some iPad issues they are having with the planter monitoring system in one of their tractor cabs. Marty Zwerk had been out planting earlier, but we find their 32- and 48-row John Deere planters parked in the equipment shed. Mike makes a couple of quick adjustments to the iPad.

As we’re about to head out, Marty arrives and asks Mike to take a look at his Precision Planting RowFlow system. It’s another simple fix, and one which Mike is happy to take care of because he knows it will be time well spent. “These are valuable customers and I really want to make sure their planters work to maximum capabilities,” he says. “I know they will be investing more in precision with us next winter.”

Delivering a replacement guidance system can solidify a customer relationship. “We pride ourselves on having loaners,” Houghtaling says. “This service gives us a competitive advantage.”

3:45 p.m. On our way back to the store, we drive by Brian Bierlein who is planting and everything looks good. I ask Mike about several brush fires in roadside ditches that we pass. While they struck me as odd, Mike hadn’t noticed them, because they are a common occurrence this time of year in the area. “It’s an old-school pest management technique,” he says. “There’s a sugarbeet leaf miner that lays eggs in the fall and in spring, some farmers will burn the ditches before the eggs hatch.”

4:02 p.m. We arrive at the dealership and Mike checks in with his team. All is relatively calm. He’s told that a customer stopped in earlier looking for a replacement lightbar and Mike remembers they just received the same system on trade 2 days ago. He assembles the necessary pieces, grabs another Coke from the fridge and we are out the door.

4:25 p.m. We meet Ryan Schumacher at his farm in Munger. He is thrilled that Mike was able to deliver a replacement system. It’s a 10-minute stop, but clearly one that Mike wanted to fit in today. “We pride ourselves on having loaners for our customers so they don’t have to sit around waiting for parts to get fixed,” he says. “This service give us a competitive advantage and I’ve even borrowed some equipment from my own farm so customers can be up and running faster.”

4:48 p.m. As we make our way back toward the dealership, Mike stops at his family farm to see how things are progressing. Mike’s dad Kent, and his uncle, Dave, are both there getting equipment ready for planting. They discuss field conditions in the area and Mike says he plans to drop by later tonight to make some planter adjustments.

5:20 p.m. We pull into the parking lot at P&C Ag Solutions for the last time today. The sign in the window indicates that the office closes at 3 p.m., but Mike says that the time is somewhat arbitrary. “Basically, that is how long someone is guaranteed to be here,” he says.

5:34 p.m. The office is quiet, although Gretchen is still wrapping up some of the day’s paperwork. Mike takes stock of the day’s progress and makes a mental checklist of what he needs to accomplish tomorrow. But today wasn’t nearly as chaotic as it could have been. After 56 ounces of Coca-Cola, 8 customer visits and 1 purchased implement caddy, I have a deeper appreciation and understanding of how an independent precision farming dealer spends his day in the cab.