Eric Mensen, integrated solutions specialist at Van Wall Equipment, maintains constant communication with his customers and coworkers at Van Wall’s Story City and Nevada, Iowa, locations. It’s a practice that proves successful for the dealership today, and Mensen predicts it will become even more important to the role of a precision farming specialist in the future.

Van Wall was Precision Farming Dealer’s 2021 Most Valuable Dealership and Farm Equipment’s 2016 Dealership of the Year, so our editorial team thought it would be wise to spend a day with one of the dealership’s precision farming specialists to give you a deeper understanding of how its award-winning practices influence the precision team’s daily work and responsibilities.

8 a.m.

It’s windy and a brisk 26 degrees as I arrive at Van Wall Equipment of Story City, Iowa. The John Deere dealership has 32 stores — 29 in Iowa, 1 in Illinois, 1 in Kansas and 1 in Nebraska. Inside the Story City location, I find Eric Mensen sitting at a desk in his office, working on his computer. Eric has been with Van Wall for about 12 years, starting as an intern before he was hired on as an integrated solutions specialist.

8:09 a.m.

After quick introductions, Eric and I depart for his first stops of the day, his house to pick up a tool he needs and a research company’s equipment shop. He’s building a second Gator equipped with auto-steer for the company, and he needs to inspect the first one to make sure he has everything ordered for the latest iteration.

On the way, Eric tells me about his customers and their typical farming practices. He describes the fields as “flat, black and square,” with most customers using conventional tillage, although he notes there are some strip-tillers in the area. Most grow corn and soybeans, as one would expect in Iowa, but a few grow sorghum and seed corn as well.

“Because of the seed corn, we have a lot of odd configurations of planters,” Eric says. “26-row planters are not uncommon around here.”

8:37 a.m.

Eric gets a lot of windshield time, especially during the planting season. He puts close to 30,000 miles a year on his vehicle, and he recalls a single day when he drove more than 300 miles during his work hours.

Using a harness hooked up to his SUV, Eric attempts to connect a monitor needed to diagnose a Meyer manure spreader with a scale that continuously counts up.

Van Wall’s integrated solutions specialists are typically assigned customers based on which salesperson the customer bought from, so there’s some overlap of specialists’ geographical territories. The dealership also uses John Deere’s ExpertConnect, the customer service ticketing system, meaning Eric occasionally ends up taking calls outside of his usual territory.

During the winter months, he estimates that he’s working in his office more than 50% of the time, dealing with data, crop insurance and other responsibilities.

9:22 a.m.

After bumping down a muddy gravel road, we arrive at the research company’s facility, and a man named Tyler takes us inside to the original Gator with auto-steer. The company uses the Gator to pull a Roundup wiper through standing wheat and oats for research trials. Eric inspects it, gives Tyler an update on the project and heads back to the car for the next stop — his office at the Nevada store to pick up some parts.

9:45 a.m.

As we pull into the Nevada store’s parking lot, Eric gets a call from Renae Pruess, Van Wall’s supply manager, about inventory. That leads to Eric making two more calls to answer her question about financing to reconcile her records.

Throughout our trip so far, and as I’ll come to find throughout the day, Eric fields a lot of calls from clients and coworkers. He answers everyone’s questions efficiently, fostering the constant communication he sees as critical to serving modern farm operations.

Eric says he tries to talk to all of the salespeople, the parts and service department, and Van Wall’s agronomist every time he’s working from the Story City and Nevada stores. He tells them about conversations he’s had with his customers, some of which are totally unrelated to precision. Eric recalls a customer who asked him, “the GPS guy,” for tire recommendations.

“The best reason I can come up with for them asking me is that they know I’m in and out of a lot of machines at operations that are using precision equipment,” Eric says. “They’re looking for an opinion from somebody who stands nothing to gain if they buy the tires and who deals with people who farm like they farm.”

“The mindset has gone from parts and pieces to looking at a farmer’s operation as a whole…” – Eric Mensen, Integrated Solutions Specialist, Van Wall Equipment

But those conversations give him — and the sales team — valuable insight into the operation and opportunity for the dealership to provide solutions.

“We’ve got to look into the future and not necessarily sell the farmer what he’s asking for,” Eric says. “Based on previous conversations about where he wants to go with his operation, maybe we can upsell him on something slightly newer because 3 years from now, that’s what he’s going to need anyway.”

9:51 a.m.

Eric goes into his office to grab a couple of parts and says hello to some of his coworkers while he’s there. It’s not long before we’re back in the car on the way to a customer’s farm shop to work on a tractor and strip-till bar.

Eric tests a new harness connecting a customer’s John Deere 9470 RX tractor to a Kuhn Krause Gladiator 1205 strip-till bar.

10:24 a.m.

At the shop, Eric needs to upgrade the harness connecting a John Deere 9470 RX tractor to a Kuhn Krause Gladiator 1205 strip-till bar. The setup used somewhat of a cobbled-together harness last season, and the customer is upgrading to a single, longer harness.

Eric connects the harness, pulls the tractor out of the shop and powers up the bar. Everything is working correctly, and he calls the customer to let him know, apologizing to me in advance for the farmer’s colorful language.

They talk about the work Eric just did, and the farmer warns Eric that he may need a refresher on operating the bar in the spring. Eric says he can do that, tells the farmer where he left the old harness and says goodbye.

As he’s turning out of the farmer’s driveway, Eric’s phone rings. It’s Scott Meldrum, his manager, asking him to call one of the other precision specialists who’s working on a strip-till AutoPath issue for a customer. The phone calls and driving continue as we make our way to Eric’s next project.

11:12 a.m.

Along the way, Eric gives me an example of how inter-department communication solved a compaction issue for a customer about 20 miles south of the Story City dealership. Eric noticed that the customer’s ripper was oversized for his tractor, and he asked Van Wall’s on-staff agronomist how deep the customer should be ripping.

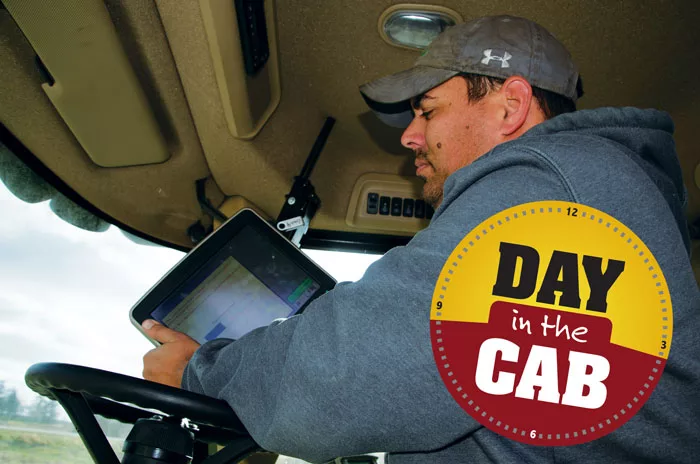

Check Out the Day In the Cab Video

Take a closer look at a day on the job with Eric Mensen, integrated solutions specialist at Van Wall Equipment, in exclusive video filmed during Precision Farming Dealer’s Day in the Cab. visit www.PrecisionFarmingDealer.com/ditc.

The latest installment of the Day in the Cab series is brought to you by SWAT MAPS.

“We started doing the math, and there’s no way that tractor could pull that ripper at the depth that it needed to be at the speed he needed to go to get it done,” Eric says. “We brought it up to the customer, explained our thought behind it, and he agreed.”

Eric went to a Van Wall salesman and suggested setting up the customer with a bigger tractor and smaller ripper. A few weeks later, the customer was out on the field with his new bigger tractor and bigger ripper. That purchase led to conversations about his planter’s performance, a non-John Deere model from another dealer, and then the sale of a new John Deere planter that same year.

The customer continued talking with Eric about the TruSet technology he liked on the new cultivator, and Eric took that information back to the salesman.

“Now he’s being quoted a 2660 vertical till unit,” Eric says. “All of that stemmed back to me and the agronomist trying to figure out why his corn was 2 feet shorter every 20 feet.”

11:39 a.m.

After all the driving we’ve done this morning, I have no idea where we are and where it is in relation to either of the Van Wall stores I visited today. But we’re where we need to be — a piece of land that serves as a customer’s equipment and silage storage space — as Eric pulls up next to a Meyer manure spreader with a Raven RCM Level3 controller that he’s here to service. The spreader’s scale continuously counts up, even when there’s nothing in it.

Eric and his coworker installed the controller when the customer initially purchased the spreader, back when Van Wall was a Raven dealer. After Raven and John Deere ended their relationship, Van Wall’s integrated solutions manager and application precision specialist worked out a deal with the local Raven dealer, Stutmans Inc. in Hills, Iowa, so Van Wall could continue selling and servicing Raven equipment to its customers.

On this particular spreader, the Raven dealer advised replacing a harness, but that didn’t solve the issue. Eric will check it and attempt to calibrate the spreader if the harness is working.

To do this, he’s using his SUV to power a monitor hooked up to the spreader with a homemade harness. After some fiddling with the harness, the monitor turns on. Eric gets a Merlo telehandler with a 1,500 kg. weight to place in the spreader to see if a steady weight will register. It doesn’t, so Eric will have to call someone else to come back to diagnose the issue.

In the winter months, Eric spends more than half his working hours in his offices at the Story City and Nevada stores. During the summer, Eric is often so busy helping customers that weeks can pass between his stops at the office.

12:33 p.m.

At this point, we’re both freezing from standing out in the wind. A warm lunch in Ames, about a 20-minute drive from the farm, is our next stop.

1:02 p.m.

After lunch, I ask Eric how his job has changed since he first started working as a precision specialist.

“Technology is just evolving so much,” Eric says. “I’ve been in it considerably longer than the average specialist, and I’ve experienced the change happen. It is not the same position that I started in. It’s drastically different.”

Twelve years ago, he and the other integrated solutions specialists were still demoing auto-steer to farmers and explaining how precision agriculture technology could improve their operations. Now, much of this technology comes standard on equipment, and Eric does less “nuts and bolts” work.

“We’re doing a lot less fixing and a lot more fine-tuning of the machines,” he says. “The mindset has gone from parts and pieces to looking at a farmer’s operation as a whole.”

At 33, Eric is one of the oldest people in his department. He says he’s “an old guy” when it comes to technology and makes an interesting observation about who the dealership’s customers, who are generally older, trust with technology.

“Younger people immediately have credibility because it’s technology, and technology is a young person’s game in their minds,” Eric says. “When I or someone older shows up at the farm, we have more credibility on the mechanical side because that’s what the position was when I got into this.”

With so many years of experience, Eric has built trust with his customers on technology and data, but he knows the technology — and the role of an integrated solutions specialist — will continue to change. In the future, he believes his work will center around making the systems on the farm work together and getting the most out of them.

1:23 p.m.

A John Deere 9670 STS combine parked at the end of a gravel parking lot and a frigid gust of wind greet us at Eric’s last customer stop of the day. He needs to collect the customer’s data and remove the display from the machine because the customer recently sold the combine. It doesn’t take long, and soon we’re back on the road to the Story City dealership.

2:15 p.m.

Once we arrive at the store, Eric returns to his desk to check emails while I get my camera and tripod set up. We’re recording a couple of videos about some of the themes we’ve talked about throughout the day. (You can see them here.)

2:48 p.m.

We finish up the videos, and I thank Eric for letting me ride along for the day as I pack up my equipment. I’m off to visit a strip-tiller about 20 minutes north of Story City before he speaks at a meeting for local farmers. What proved to be a busy but very productive day is just getting started!