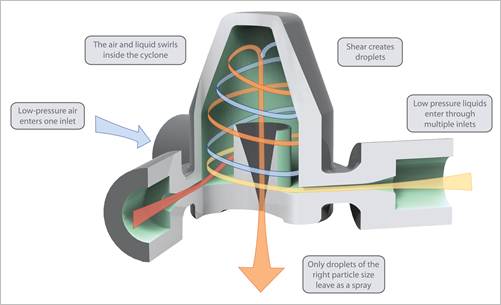

Product development firm Cambridge Consultants is harnessing the power of a cyclone to better mix and spray liquids.

The new Vortik technology allows different liquids to be mixed at the point of spray without altering the spray characteristics – opening up the possibility of new applications in agriculture, consumer and industrial products, and healthcare.

Conventional atomizers use either a high pressure or high air flow to create a spray. This new fluid handling technology combines low-pressure air and liquid in a specially shaped cyclone chamber. Shear between swirling air and the liquids creates the desired droplet size for spraying.

Simon Smith, associate technology director at Cambridge Consultants, said: “From field to factory – or even in the beauty salon – this cyclonic spray technology will allow greater control of sprays. Farmers will able to boost yields and reduce waste by more accurate application of pesticides and other products on their fields. The ability to mix liquids on demand in a cyclone chamber will allow instantaneous control over chemical composition.

“In the personal care industry, the spray technology can offer user control – for example, on-demand color matching in foundation or spray tanning. And the greater control over particle size means less of the spray is breathable – an issue of increasing regulatory concern.”

In the pharmaceutical world, allowing active ingredients to be mixed at the point of delivery overcomes shelf-life and stability issues whilst minimizing waste. Example applications are medical adhesives, as well as industrial glue.

Cambridge Consultants will be demonstrating Vortik – along with other technologies to support precision agriculture, such as radar sensors – at the Agritechnica International Exhibition, November 12-15, in Hanover, Germany, hall 17, stand C38.