For over 35 years, members of the American Society of Agricultural and Biological Engineers (ASABE) have recognized and honored the most innovative advancements in engineering in the areas of agriculture, food and biological systems with the AE50 Award. The Products selected save producers time and reduce cost and labor, all while improving safety.

To be eligible for the award, each development — which could be a component, machine, structure, system, end product or procedure — must embody the application of new technology or the innovative application of an older technology. The technology must be new to the entire industry, not to an individual company. Each year, an international panel of industry experts in technology, design and product development gather to evaluate the entries and select up to 50 products for recognition. Below is a selection of the 2025 winners. Full coverage of the winners can be found on No-TillFarmer.com.

Unverferth Air Command Section Control for Pro-Force Dry Fertilizer Spreaders

The Air Command section control system for the Unverferth Pro-Force dry fertilizer spreader uses pneumatics to redirect fertilizer from the belt-over-chain conveyor for precise 4 section control. This innovative system saves the user money by not over-applying valuable dry fertilizer in the field and has a faster return on investment for the purchaser due to the simplistic design. A hydraulically operated blower fan pressurizes the air manifold and when a valve assembly opens, air flows through, redirecting fertilizer to the other sections. When this happens, the belt-over-chain conveyor automatically slows down so it doesn’t over apply on the active sections. The Air Command can shut off any of the four sections at any time, independent from one another. The system communicates with the standard ISOBUS rate controller and will follow a customer’s programmed coverage map to open/close air valve assemblies to only apply fertilizer where it’s needed. The factory-installed Air Command section control system retails for $17,150.

Unverferth Mfg. Co., Kalida, Ohio

Bourgault Intelligent Control – BiC

Bourgault Intelligent Control sets a new standard in seeding technology with a focus on simplicity, flexibility and integration. Its intuitive user interface allows operators to learn the system quickly, reducing training time and improving ease of use across the farm. The wireless monitor control system eliminates the complexity of traditional wired installations, making setup and replacement faster and more efficient. Unlike tank-based systems, Bourgault Intelligent Control is focused on the product application itself. Operators select the product and rate allowing the system to optimize tank configurations selecting maximize efficiency. Seamless integration with leading OEM platforms — including John Deere Operations Center and CNH FieldOps — gives farm managers real-time visibility and control in the field. BiC retails for $60,000.

Bourgault Industries, St. Brieux Sask.

MacDon Industries FD2 PLUS FlexDraper

MacDon didn’t set out to build just another flexing cutterbar draper, it took its legendary FlexDraper platform and pushed ground-following performance to the next level, the company says. With over 2 inches of extra flex at the cutterbar, it hugs the ground tighter, reaching deeper into low spots and scooping up every last bit of available crop. Unlike other flex headers, the FD2 PLUS flexes without compromise, maintaining MacDon’s close reel-to-cutterbar relationship for smooth, consistent feeding. The ultra-light instant float response keeps the header moving effortlessly with the land, cutting closer, capturing more crop, and helping your customers get more from every harvest. The FD2 PLUS retails for $170,000-$240,000 CDN depending on size.

MacDon Industries Ltd., Winnipeg, Man.

Great Plains Manufacturing BD7410

The Great Plains BD7410 patent-pending transport system ensures ideal weight distribution between the hitch and transport axle, keeps the transport tires out of the way during planting, and provides a simple operation to rotate from transport to field position. Three row spacing options, including five inch, offer customers unmatched versatility when seeding specialty crops. Up to three separate seeds can be metered into the furrow at once. The BD7410 is the only minimum-till drill that can rotate from up to 20 foot working width to less than 10 foot transport width. Hydraulically actuated field and transport locks maintain safety while providing convenience. The BD7410 retails from $69,000-123,000.

Great Plains Manufacturing, Salina, Kan.

Salford Group AB230CD Chassis Mounted Air Boom

The Salford AB230CD chassis-mounted air boom applicator is purpose-built for the Case IH Trident 5550 Dry Hi-Flow, leveraging its unmatched hydraulic capacity for faster speeds, higher product rates, and wider coverage with reduced compaction. Equipped with an 80-foot boom and 225 cubic feet triple-bin hopper, the AB230CD maximizes daily productivity while delivering precise, variable-rate application of dry fertilizers and micronutrients like sulfur and zinc. The unique triple-bin design eliminates pre-blending by enabling two main products and a micronutrient to be applied at independently prescribed rates. Operators benefit from seamless integration with the chassis universal terminal, enhanced boom ride for rough terrain, and optional drop-tubes for in-season applications beneath the canopy. With Salford’s proven engineering, commercial applicators achieve fewer passes, higher throughput and extended earning potential with one high-performance machine. Base retail price for the AB230CD is $255,000.

Salford Group, Salford, Ont.

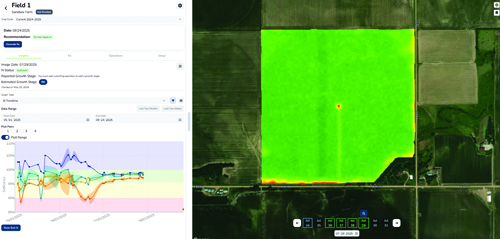

Sentinel Ag Sentinel Application Advisor

Sentinel Ag’s approach combines two established technologies in a way that hasn’t been done before for nitrogen management, the company says. It uses a model–sensor fusion strategy, bringing together crop growth models and image-based sensing so they work together rather than separately. The models project how a crop is likely to grow and estimate its needs under different conditions, while the imagery and insights provide a snapshot of what’s actually happening in the field, capturing plant health and variability in real time. By combining these perspectives, the platform generates recommendations that are both forward-looking and grounded in current conditions, giving farmers a practical, reliable guide for managing nitrogen. To Sentinel’s knowledge, this is the first time these two approaches have been applied in parallel to inform nitrogen decisions, creating a more adaptive, data-driven solution that is a high-value tool to farmers and agronomists. The retail cost of the Sentinel Application Advisor is $13.00 per acre.

Sentinel Ag, Ithaca, Neb.

Agrifac AiCPlus 3S

Agrifac AiCPlus 3S is an OEM-integrated, camera-AI spot-spraying system that delivers reliable, plant-level application at commercial field speeds. Its defining advantage is triple-layer precision with confidence-gated detections and physics-aware nozzle control that slashes chemical use while protecting yield and the environment. New in 2025, AiCPlus 3S is a new product — an industrialized, truly factory-equipped realization of vision-guided selective spraying on the Condor platform, not a modification of a prior sprayer option. Distributed boom-mounted cameras, real-time inference, and predictive nozzle timing place droplets exactly where targets will be, eliminating pre-mapping passes. Agronomic value comes from per-plant application maps and seamless ISOBUS workflows, turning the sprayer into a field-intelligence hub. Compared with other OEM solutions, AiCPlus 3S uniquely combines plant-level selectivity, commercial-speed uptime, and factory fit, enabling practical, scalable input reduction for modern farms. Pricing for the AiCPlus 3S varies from $150,000-$225,000, dependent upon working width.

Agrifac Machinery, Seward, Neb.

Sudenga Industries Double Barrel Power Sweep

Sudenga’s Double Barrel Power Sweep is the first high-capacity grain bin unloading system designed to install in economical 13-inch grain dryer floors — eliminating the need for costly bin foundations and tunnels. This innovation significantly reduces installation time and expense for both contractors and bin owners, the company says. Its most unique feature is the flexible conveyor configuration, which can stop at the center of the bin or extend through the full diameter, adapting to site-specific needs. The zero-entry sweep remains permanently mounted inside the bin and is driven externally via heavy-duty gearboxes, enhancing safety and reducing labor. With a capacity of 6,500 bushels per hour, it delivers high performance with low horsepower requirements and minimal maintenance. Ideal for bins up to 93 feet in diameter with eave heights up to 100 feet. The Double Barrel Power Sweep retails for $20,000-$90,000, depending on the bin diameter and system format.

Sudenga Industries, George, Iowa

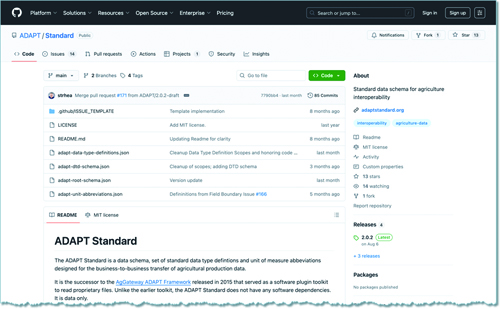

AgGateway ADAPT Standard & ADAPT Standard Plugin

AgGateway ADAPT Standard is a data model, set of standard data type definitions and unit of measure abbreviations designed for the business-to-business transfer of agricultural production data. It is the follow-on to AgGateway’s ADAPT Framework which was first released in 2015. The ADAPT Framework is an open-source application that reads and writes various field operations data files, including ISOXML and proprietary OEM file formats. Unlike the ADAPT Framework, the ADAPT Standard is not limited to Microsoft development technologies. AgGateway has also released an ADAPT Standard Plugin to support use of ADAPT Standard in existing ADAPT Framework-based solutions. The ADAPT program is free to use, open-source software.

AgGateway, Arlington, Va.

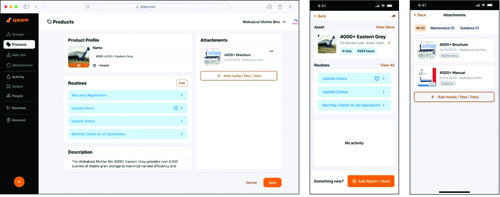

Gripp Rendezvoo

Gripp Rendezvoo is the world’s first Equipment Relationship Management (ERM) platform, an Asset-Centered Relationship Management hub connecting OEMs, Distributors and other trusted advisors in real-time to support customer breakdowns, preventative maintenance, equipment questions, conversations, and access to relevant and timely equipment information at the moment of need. Gripp Rendezvoo builds stronger brand relationships while giving equipment owners something they’ve always wanted, an easy, transparent and real-time way to know they are being taken care of by those they trust. Gripp Rendezvoo provides many services, including: always-on customer care, delivery of the right information, at the operator’s moment-of-need, centralized communication, service & support across equipment, teams and customers, unmatched product insights directly from operators and a central place to manage customer and channel strategies from factory to field. The cost for Gripp Rendezvoo starts at $99 per month, plus a one-time charge of $25 per asset tagged.

Gripp, Inc., Kewaskum, Wis.

Grain Weevil Corp. Grain Weevil

The Grain Weevil is a grain bin safety and management robot that protects farmers by doing the work no human should. Lowering long-term risks due to dust exposure as well as avoiding entanglements, entrapments and falls. The Grain Weevil doesn’t just make bin work safer — it makes it more productive and profitable by controlling risk, minimizing costs and actively optimizing stored grain. Grain Flow Intelligence is a new category of autonomous technology that transforms post-harvest operations by automating and optimizing grain movement, conditioning, and control across bins, piles and storage facilities. Grain Weevil is the first platform to deliver GFI — replacing manual clean out and reactive storage practices with precision movement, protocol-driven management, and zero-entry safety. The complete Grain Weevil Package retails for $15,500.

Grain Weevil, La Vista, Neb.

PTx Trimble OutRun | Tillage

Getting tillage done in a timely manner allows for faster residue decomposition in the fall and timely planting in the spring. OutRun | Tillage is a retrofit autonomy kit that is installed onto existing tractors to enable fully driverless operation of the tillage task. The solution allows an operator to plan, initiate, control and monitor the autonomous tillage mission from an app on their smartphone, allowing farmers to perform tillage at the optimal time of the season regardless of their labor availability. The system extends the OutRun autonomy system beyond the grain cart with an entirely new workflow for tillage and a kit to monitor the tillage tool. The retail cost for the OutRun | Tillage consists of a one-time hardware cost of $55,000 and a recurring annual subscription of $9,000.

PTx Trimble, Westminster, Colo.

AEF Vision Zero - Road Safety

The objective of Vision Zero is to eliminate the loss of life caused by on-road accidents. It is crucial for the agricultural machinery sector to contribute to this goal by reducing the likelihood of accidents and minimizing the associated consequences. One effective approach is to facilitate the sharing of vehicle positions, driving intentions, and potential hazards, such as vehicle breakdowns, among different road users. Cooperative Intelligent Transportation Systems (C-ITS) is a solution designed to support this objective. By employing radio technologies, C-ITS enables the data exchange among various types of vehicles. This shared data encompasses real-time information about the driving situation, as well as additional details and other indicators of potentially dangerous situations. The AEF has established a unified implementation for all agricultural vehicles. This approach not only reduces integration efforts but also ensures consistent system behavior across different equipment brands.

Agricultural Industry Electronics Foundation AEF e.V., Frankfurt/Main Hesse Denmark

Synk Bin Controls

Synk Bin Controls use a mix of advanced sensors and software to monitor grain in a storage bin and turn on fans as needed to keep the grain in optimum condition. With modular automation, adaptive grain handling, superior data integration and quicker decision-making capabilities than any other system available, it’s designed to make one of the most important parts of farming — storage and optimum conditioning of stored grain — simpler, smarter and safer. The system uses advanced temperature and moisture monitoring cables that are suspended from the roof of the grain bin. Sensors on the cables and CO2 monitors at top and bottom of bin provide data that can be used for turning on aeration fans used to dry and/or cool off grain. Fans can be turned on automatically or manually using a touch-screen console, and eventually via remote control using a cell phone app, MySukup.com. Synk Bin Controls retail for $15,000-$23,000, depending on grain bin diameter.

Synk, Ames, Iowa

Bish Enterprises FiberCut 414 Model

The FiberCut 414 is an innovative hemp harvesting solution that eliminates the need for a combine or header — requiring only a tractor to complete the harvest. Its most unique feature is a hydraulically controlled lifting and tilting cylinder with modular adjustable arms, allowing operators to harvest hemp of varying stalk heights with precision, including a lowered position of 116 11/16 inches. Featuring a 14-foot cutting knife — the longest available in its category — the FiberCutT 414 achieves up to 16.99 acres per hour at 10 mph. Over an 800-acre harvest, this translates into time savings of up to 24.85 hours compared to competing products. By lowering entry costs, simplifying logistics, and improving fiber quality, the FiberCut 414 represents a breakthrough in harvesting hemp, kenaf and other tall biomass crops. The FiberCut 414 retails for $99,995.

Bish Enterprises, Giltner, Neb.

Carlos Mainero y Cia SAICFI Mainero 1045 Row-Independent Sunflower Header

The Mainero 1045 preserves previous model performance capabilities while increasing working width but also includes row-independent ability, improve and add some adjustments and eliminate tilting need on a transport trailer. Folding pans ensure the header fits transport width on the trailer without tilting it. Improved pans passage provides unrestricted stalks incoming and avoids jamming. New adjustment is added to individually set shield height with respect to pans and reel, reducing MOG intake. Reel fingers are tangent to the pipe -not perpendicular- completely eliminating the lean to “nail” and “fly forward” heads. Both sickle bar and auger have central drives to reduce fenders width avoiding harvest losses at the outer fenders off the rows and an innovative modular manufacturing system simplifies its assembly at destination. The Mainero 1045 retails for $45,500-$50,600, varying by size.

Carlos Mainero y Cia SAICFI, Bell Ville Cordoba, Argentina

Kelley Manufacturing Co. KMC 7600 Litter Pulverizer

The KMC Litter Pulverizer is an innovative solution designed to enhance the efficiency and consistency of poultry litter management in commercial operations. This machine features the industry’s first dual-stage rotor system, combining a high-torque front rotor with a counter-rotating flail rear rotor to break down dense ‘cake’ litter into dry, highly aerated material in a single pass. This advancement reduces processing time by 40–60%, eliminates the need for additional equipment, and decreases fuel use, all while providing more uniform litter conditions. Based on extensive field testing and detailed rotor dynamics analysis, the KMC Litter Pulverizer marks a significant engineering improvement, combining proven principles with grower feedback to deliver a measurable improvement in both litter management and overall poultry production efficiency. The KMC Litter Pulverizer sells for $12,283.

Kelley Manufacturing Co. Tifton, Ga.

RCI Engineering T9096 Tractor-Powered Table Ag-Bagger

The T9096 enables producers to use their own power units while gaining the efficiency of a rear unloading table Ag-Bagger. The T9096 provides higher capacity, heavy-duty components and easy-to-use controls all while maximizing efficiency to meet the growing demand of forage operations. Rated at up to 350 horsepower, and with a 12-foot Feed Table combined with 10- and 12-foot Tunnel options, the T9096 works for growing operations that have expanding forage needs. This unit is an alternative to self-propelled models, offering the flexibility of using the producer’s tractor for power, while keeping up with today’s large self-propelled forage harvesters. The T9096 is a new product offering, building off a concept developed by Ag-Bag in the 1990s to take advantage of today’s higher tractor PTO horsepower while incorporating features such as the anchor system, independent wheel braking, hydraulic bag boom, sweeping tunnel cleanout and wider feed table. The T9096 retails for $300,000.

RCI Engineering, Mayville, Wis.

Danfoss Power Solutions ED3

Danfoss Editron has launched a high power bi-direction onboard charger and ePTO for off-highway battery electric machines. ED3 boasts an industry leading 44kW charge rate, supporting larger batteries required for heavy duty, demanding off-highway applications. Further, ED3 achieves this higher charge rate using AC power. Compared to DC fast charging, AC charging infrastructure is simpler and lower cost for end users to install. Additionally, battery electric machines using ED3 44kW ePTO are able to provide significant value to end user that ICE machines cannot. The AC ePTO can run compressors, pumps, motors, and provide micro-grid connection in the field by supplying 400 / 480 volt 3-phase power. The DC ePTO provides regulated power to high voltage machine implements and external devices. An isolating transformer allows charging and ePTO to interface external equipment safely. The charging power and critical features of ED3 are enabling the next generation of battery electric off-way machines.

Danfoss Power Solutions, Ames, Iowa

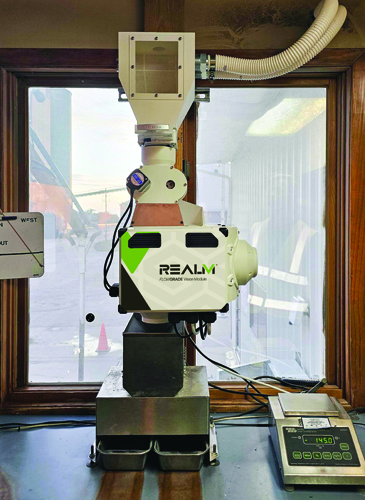

RealmFive FlowGrade Vision Module

The FlowGrade Vision Module is an in-line, AI-driven imaging system that captures and classifies grain kernels in real time as they flow through the grading process. By applying advanced machine vision and trained machine learning models, the module detects foreign material, broken kernels, heat damage and visible mold instantly, eliminating reliance on subjective human visual inspection. It can operate independently or as part of the modular FlowGrade continuous grading system, delivering accurate and consistent results to operators, enterprise systems and customers. The module is available as a $15,000 year-one lease with base annual recurring subscription of $5,000, depending on crop requirements.

RealmFive, Lincoln, Neb.

Forest Concepts Advanced Dryer Control Systems for Belt Dryers

With 3 years of support from the USDA National Institute of Food and Agriculture SBIR program, Forest Concepts has developed and proven an advanced control system for biomass dryers that improves product uniformity, reduces the need for operator experience, and improves thermal efficiency. Forest Concepts’ Dryer Control Automation frees dryer operators to do other duties or to manage a broader set of production systems in addition to overseeing dryers. Overall dryer thermal efficiency is improved by increasing airflow and only providing the heat needed to drive moisture diffusion and evaporation from the biomass. The increased efficiencies significantly reduces required residence time and energy consumption, which can result in a reduction in the physical size of the dryer and the resulting CAPEX. Each dryer control system includes hardware and software. The dryer control technology is supported by Software as a Service (SaaS) accessible through mobile and web applications. The price for the Advanced Dryer Control Systems is $500,000.

Forest Concepts, Auburn, Wash.