Pictured Above: Christopher Hudson and his father, Curt, check their electronic tablet to assess the performance of their 48-row planter. Photo courtesy of The Mosaic Co.

Farming by the inch is what propels no-till farmers Curt and Christopher Hudson closer to higher yields and increased profitability.

The father and son partnership sharpens the cutting edge of precision-agriculture management of their 2,600 acres of corn and soybeans grown near Crawfordsville in west-central Indiana.

“When we see opportunities to push the upper limits of production, we’re very interested,” says Curt, who began no-tilling their farm ground in 1980. “Our goal is to gather every bit of information we can — soil, hybrids, herbicides and populations. We want to know what’s going on in the field, and we want our decisions and our choices to be verified with data.”

Christopher says his dad has always been an early adopter, but Curt readily admits that his son’s technological savvy has been a large help in moving the operation forward.

“We certainly wouldn’t be doing a lot of the things we’re doing without him taking the lead,” Curt says.

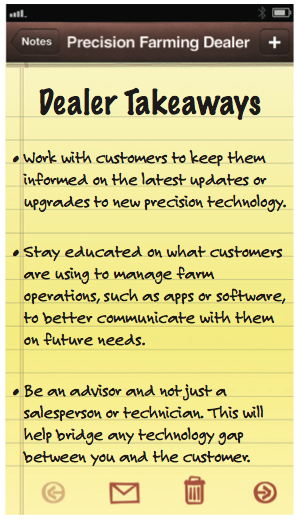

Tablet in the Cab

A recent addition to the Hudsons’ precision-farming toolbox is a third-generation Apple iPad tablet that has proven to be a valuable asset.

As an extension of the Hudsons’ Precision Planting 20/20 SeedSense monitor, a FieldView app enables the iPad to present a high-resolution Google map image of the field, overlaid with critical data from the planter.

The 20/20 provides plenty of row-by-row information — singulation percentage with skips and doubles, population, row-unit weight, ground contact and more. Precise seed placement in a high-residue environment is a critical component of maximizing yields in their continuous no-till system, Christopher says.

| “Precision ag management, in itself, doesn’t improve productivity — but it enables us to manage our crops in ways that can…” |

“When I got it last year, I really just thought it would be a cool toy to have, but it’s been a big help when I’m planting, and I think the applications for it on the farm are very extensive,” Christopher says. “The iPad gives you a real-time visual representation of what’s going on with each row instead of just displaying numbers on a screen. The rows appear in a different color, and that enables you to quickly identify and address problems. If there’s an issue with singulation or anything else, you can immediately do something about it.

“We haven’t fully analyzed the numbers yet, but I think it’s pretty clear that enhanced planter performance alone will make this a good investment.”

The FieldView app itself is free. A base kit with FieldView module, harness and bracket from Precision Planting connects the iPad to the 20/20 system.

There’s a lot going on behind the John Deere 8345 crawler tractor the Hudsons use for planting. It pulls an 80-foot John Deere DB80 48-row planter set for 20-inch rows, replacing the twin-row planter they had been using.

“We really like the planter because it maximizes our planting-time labor efficiency. But that’s a lot of rows to monitor,” Christopher says. “The iPad and FieldView makes the information more meaningful and accessible.”

Curt adds that quicker and more convenient access to planter-performance information also helps reduce the stress of keeping track of what’s going on in 48 rows.

Better Data Management

Enhanced planter performance is just the beginning of the iPad’s utility at Hudson Family Farms. All of the planting data resides on the tablet, so no downloading is required and the information becomes portable. Christopher and Curt can disconnect the tablet from the 20/20 and take the data to the office or the field.

“You can mark a rock or a tile problem,” Christopher says. “Then you can take the iPad with you to the field later, and go right to the spot.”

As a scouting tool, the app and the iPad give the Hudsons the ability to incorporate field notes and photos related to the planter-performance information.

Fertilizer, herbicide, insecticide and fungicide data is mapped using Farm Works computer software to help assess efficiency.

The Hudsons also use Precision Planting’s YieldCheck app for the iPad that takes scouting information, such as ear and kernel counts, and calculates yield predictions. While YieldCheck doesn’t correlate survey locations, Christopher and Curt can use “drop pins” to make note of yield estimations by using the GPS functionality of the iPad.

A DTN app provides access to the latest commodity cash and futures market information to support the Hudsons’ marketing decisions, as well as timely weather information.

The tablet plays an important communication role and also streamlines planter-data functionality, Christopher says. The Hudsons can download any web-based information relevant to their farming operation and have it right there in the tractor cab.

The iPad is also an easy way to communicate with retail partners, agronomists and other support resources.

Social media is another important function of the electronic tablet. The Hudsons are currently rebuilding their farm’s website, but they utilize their Facebook page to post photographs, crop information and to engage with other farmers who may be facing similar production or technology challenges.

Implement Guidance

While the Hudsons were able to incorporate mobile apps into their operation on their own, Christopher acknowledges that their precision farming dealer has been invaluable in getting them where they are with farm equipment efficiency.

When the Hudsons switched to 20-inch rows for corn two years ago, they didn’t want to give up the agronomic or economic advantages of sidedressing with anhydrous ammonia. The problem was that narrower rows left very little room for placement error.

“To successfully sidedress corn, the planter pass has to be perfect — it’s a very precise environment,” Christopher says. “The tracks on the 8345 are 16 inches wide — the narrowest we could get. With 20-inch rows, that only gives you 2 inches for error on either side.”

The Hudsons worked with Evan Zimmerman, their precision farming specialist at Bane-Welker Equipment in Wingate, Ind., to find a solution.

RTK guidance and a laterally adjusting hydraulic hitch enable Curt and Christopher Hudson to sidedress anhydrous ammonia in 20-inch corn rows. Photo courtesy of The Mosaic Co.

They moved to active implement guidance with a Trimble FmX RTK system that reduces implement drift significantly compared to a passive system. They’ve been using RTK during planting for five years because it’s the only level of guidance that allows them to successfully sidedress 20-inch rows in tandem with active implement guidance for both the planter and sidedress applicator.

“Evan was instrumental in the transition and helped get us to that next step of more precise accuracy,” Christopher says. “He explained what it would take on our end, the cost and ultimately learned right along with us in refining it the last few years.”

Currently, RTK corrections are via radio signal rather than cellular. That’s primarily because the Hudsons are contracted for the radio signal, but Christopher believes cellular would open the door for wider application, including expanded fleet and information management systems that allow streamlined data sharing between the field and office.

Yield Data Collection

New technology plays a slightly more limited role at harvest.

For the 2012 harvest, the Hudsons used a Case IH 8230 combine with a 12-row Dragotec corn head, and a 45-foot MacDon draper head for soybeans.

Guidance isn’t utilized for corn harvest, but the Hudsons plan to add row guidance for the 2013 growing season.

Wide Area Augmentation System (WAAS) provides combine guidance for soybean harvest. WAAS doesn’t deliver RTK-level accuracy, but considering the size of the head and the cost of the RTK subscription, the Hudsons don’t feel it’s currently worth the extra investment.

“The margin for error in WAAS means we’re probably not fully maximizing the productivity of our MacDon draper, but by no more than a foot at the most,” Christopher says.

The Hudsons trade combines frequently, to keep them current with higher levels of technology as they become available. The most important factor is that the combine’s yield-monitor calibration is continually fine-tuned to guarantee the highest quality data, Christopher says.

Their Digi-Star grain cart scale also documents every bushel from every field. The iPad’s FieldView app is used in the combine cab at harvest to reference hybrid data, population rates and planting dates, and to make quick observations about areas where problems, such as bad singulation and low population, are apparent.

Curt and Christopher handle all yield data collection, and Farm Works software is used to manage and analyze it. Yield information obtained from the combine, grain cart weigh scale and elevator-scale tickets is correlated and refined to help the Hudsons assess hybrid and variety performance, population effects, crop protection materials and anything else tied to yield.

The Hudsons fine-tune yield data from multiple sources to gain as accurate of a production picture as possible. Combine-gathered data, they point out, is representative of yield in the field but it isn’t a perfect measurement of weight and moisture, Curt says.

Comparing and adjusting harvest yield data sources provides them with a very accurate assessment of yield and better decision making information for management, as well as historical data at a very high accuracy level.

Farm-wide yield data is shared only with respect to the analysis of specific applications. Plot-yield data, for instance, is shared for analysis with their seed supplier to aid in future hybrid and variety selections.

Yield data is also shared with the farm’s agronomic advisors to help build variable-rate planting prescriptions.

Future Goals

The Hudsons look back at historical data to identify production challenges, but they look forward to find the solutions. They’re continually looking at state-of-the-art technologies that may provide some of those answers.

In the short term, among the precision agriculture tools they will consider is Precision Planting’s DeltaForce automatic downforce-control system for their planter. Weights and sensors on each row allow for independent response to changing soil conditions.

“Advancements in planting systems, from DeltaForce to variable-rate populations and beyond, will increasingly make farmers micromanagers,” Christopher says. “In theory, every aspect of our planting is going to be managed to finer detail than today by eliminating some, and limiting other, final yield deterrents.”

Christopher would also like to test Monsanto’s FieldScripts variable-rate seeding prescription. Through FieldView, the product takes farmer inputs for yield-management zones with Monsanto seed-by-environment data to come up with a prescription that would be executed by the planter control system.

To improve labor efficiency at harvest, an autonomous tractor harvest system is also on the wish list. The technology would enable the combine operator to communicate with a driverless tractor, prompting it to follow the combine in the field and pull the grain cart alongside for grain unloading.

The Hudsons are also interested in the possibilities offered by Trimble’s ConnectedFarm program that allows live access to all farm data from any compatible web browser, along with wireless information transfer vehicle-to-vehicle or between office and field.

The continued growth, refinement and implementation of autonomous farming systems have the potential to reduce human capital requirements for crop production,” Christopher says. “If we can reduce a full time laborer during harvest, there’s obviously a financial savings to our operation for not only the labor, but the human error factor — assuming the autonomous systems are error minimal.”

Unique Dealer Relationship

The Hudsons’ aggressive approach to adopting precision farming technology has led them to forge a somewhat unusual relationship with their precision farming specialist.

While Christopher says he and his dad initially relied on Bane-Welker and Zimmerman to help with installations and upgrades, that isn’t so much the case anymore.

The Hudsons are savvy enough to handle most hardware hook-ups on their own, which means Zimmerman serves as more of an advisor/emergency contact than a typical precision specialist.

A real-time view of planter performance enables Christopher Hudson to quickly address singulation problems or other issues with any of the 48 row units of their 80-foot-wide planter. Photo courtesy of The Mosaic Co.

“Because of where we are with precision, it’s a non-traditional reliance we have on Evan,” Christopher explains. “He gets paid to make service calls and do certain things, but he’s also been able to give us firmware updates we can do ourselves, because it saves us time.”

Since both Christopher Hudson and Zimmerman are from the same generation that grew up embracing technology, they bounce ideas off one another.

More often than not, Christopher says his conversations with Zimmerman will focus on the next precision farming innovation, rather than questions about a problematic switch or how to calibrate his yield monitor.

“There’s not that generational gap and we’re speaking the same language, so that allows for some leeway with him on how we manage our precision operation,” Christopher says. “The reins are loosened a bit, but obviously if something goes wrong, it’s our problem at the end of the day. He’s busy, so with what we’ve learned over the years, I try not to call him until I’m dead in the water.”

Making a Commitment

For the Hudsons, it all comes down to more information, more accurate information and better access to information.

Three decades of continuous no-till has improved their soil, and precision agriculture techniques have positioned them to take advantage of that as well as advanced seed genetics and a growing knowledge base.

It does require a significant commitment, however.

“I’m sure there are instances where precision farming techniques save us time but, all in all, it requires us to invest more time because we have to do something with all the data we gather — there’s no point in having it if it isn’t going to be used to make better decisions,” Christopher says. “I can’t say the new technologies make it easier to grow corn, because it definitely adds another layer of management.

“I would say precision farming makes it easier to do a better job of growing corn and, for me, it makes farming a lot more interesting.”

He also points out that precise farm management demands a time commitment to adapting new technology to the Hudson’s crop production system and fine tuning to get the results they’re after.

“While precision farming advancements will aid our operation in ways unimaginable today,” he says, “I expect that advancements will help us grow larger crops from better planted, more advanced hybrids with less labor in the future — if we could only get Mother Nature to cooperate.”

Post a comment

Report Abusive Comment