Modern farm equipment has undergone a remarkable technological transformation in recent years, thanks to sophisticated advancements changing the scope of equipment operations.

When dealers and farmers are united in understanding the intricacies of these innovations, the full-scale of benefits can be taken advantage of when equipment is utilized strategically. Farmers can learn more about their operations and enhance precision from the data that modern telematics systems can provide. This operational optimization can come in the form of predictive maintenance, streamlined resource planning, real-time remote diagnostics and more.

We sat down with Vinicius Povineli, mobile electronics and connectivity product manager for Bosch Rexroth, to learn more about the unique benefits of telematics systems when paired with farm equipment.

How can real-time tracking, predictive maintenance and remote diagnostics help dealers and farmers?

Povineli: These technologies bring practical value to both dealers and farmers. Dealers benefit from the ability to track equipment in real time and monitor machine health remotely, which improves response times and service efficiency. Predictive maintenance allows potential issues to be addressed before they become major failures, while remote diagnostics ensure that technicians arrive prepared with the right parts.

For farmers, this means reduced downtime during critical operational periods, better machine performance, and fewer unexpected interruptions. It also helps extend equipment lifespan and lowers maintenance costs over time.

What is the most significant way that telematics systems can transform precision farming, specifically regarding planting, fertilizing and harvesting accuracy?

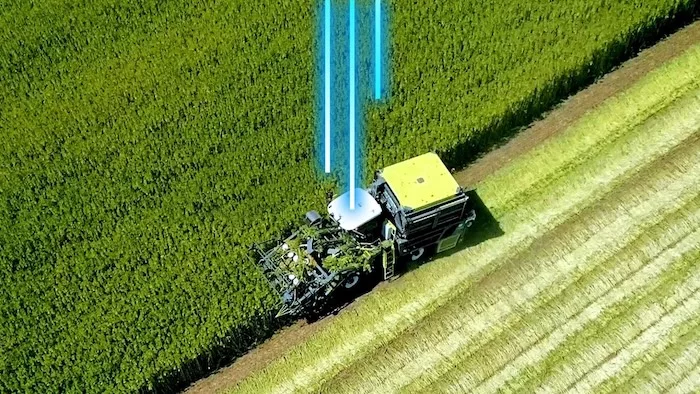

Povineli: Telematics systems enhance accuracy by enabling equipment to operate based on precise, real-time data. During planting, GPS-guided systems reduce overlaps and gaps, leading to more consistent crop emergence. Fertilizer and chemical application can be adjusted automatically based on variables such as soil type, moisture levels, and location-specific field history.

During harvest, data from yield monitors provides valuable insights that can be used to refine future planting and input strategies. This level of precision leads to better resource use, increased productivity, and greater consistency across every stage of the crop cycle.

How do sensors integrated into telematics systems help enhance precision? What kind of data from the equipment is most valuable for enhancing efficiency?

Povineli: Sensors integrated into telematics systems collect real-time data that directly supports operational precision and efficiency. These sensors monitor parameters such as engine load, hydraulic pressure, fuel consumption, soil conditions, and implement activity. When processed through a telematics platform, this data allows machines to make adjustments automatically, optimizing their performance under varying conditions.

Among the most valuable data points are fuel usage, machine location, operating hours, error codes, and application rates. By using this information, operators can reduce idle time, optimize field passes, and ensure equipment is functioning as intended — resulting in more efficient use of both time and resources.

Can these systems elevate energy savings and reduce environmental impact?

Povineli: Telematics systems contribute to both energy savings and environmental sustainability. By monitoring fuel consumption and operating patterns, these systems help reduce unnecessary idling and inefficient routing. Variable rate technology, guided by sensor data, ensures that fertilizers and crop protection products are applied precisely where needed, reducing overuse and runoff.

Well-maintained machines also operate more efficiently, and predictive maintenance plays a key role in keeping them at peak performance. Over time, these improvements lead to reduced input costs, lower fuel use, and a smaller environmental footprint, all while maintaining or improving productivity.

Are there challenges or barriers to implementing these technologies into existing equipment? How can operators overcome them?

Povineli: Integrating telematics into existing equipment can present challenges, especially with older machinery that lacks built-in connectivity. Retrofitting can require investment in hardware and may raise compatibility issues. Additionally, limited internet access in rural areas and a lack of familiarity with new technology can slow adoption.

These obstacles can be addressed by starting with foundational tools — such as GPS tracking and basic performance monitoring — and expanding as needed. Many dealers offer retrofit kits, training, and ongoing support to assist with implementation. By focusing on clear, measurable benefits, operators can gradually adopt these technologies and integrate them effectively into daily operations.