Editor's Note: This article was featured in the Farm Equipment Oct./Nov. 2025 issue.

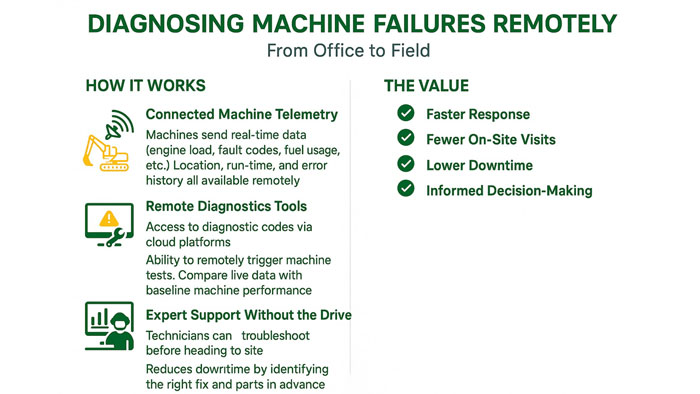

When farm equipment goes down, the clock starts ticking, and fast. Every minute of downtime costs farmers money and puts pressure on a dealership’s service team. Traditionally, the only option has been to send a technician to the field, diagnose the problem on-site, and hope they have the right parts in the truck.

United Ag & Turf (UAT) has changed that process entirely through remote diagnostics, but has pushed the remote envelope even further with its centralized support team. From a centralized Solutions Center, specialists monitor live data from more than 14,000 connected machines supported by UAT’s 48 locations.

Using advanced telematics, team members track performance metrics like engine load and hydraulic pressure, review active trouble codes, and even see the operator’s in-cab display in real time. This allows them to walk customers step-by-step through adjustments, settings or troubleshooting, often fixing the issue without a trip to the field. They can also push software updates remotely, saving hours of travel time and reducing costs for both the dealership and the customer.

“When you can see what the operator sees, it’s like having your best tech in that cab,” says Andrew Sullivan, who oversees UAT’s service operations. “We either fix it remotely or make sure the first visit fixes it.”

One of the most powerful features of UAT’s system is remote recording. In one case, a customer reported that their machine was bogging down and intermittently showing error codes.

- The centralized team set up a remote recording session, capturing 258 different data points including pressures, temperatures and voltages, all while the machine was live.

- From this data, they pinpointed a failing suction control valve without ever stepping foot on-site.

- A field tech was dispatched with the exact part needed, and the issue was resolved on the first visit.

Once a remote diagnosis is complete, the centralized team coordinates with the nearest store or field tech, ensuring they leave with the right parts, notes, and repair plan in hand. This process dramatically improves first-visit fix rates, lowers travel costs and builds trust with customers who see problems solved quickly and consistently.

Remote diagnostic support is scalable, Sullivan says. Even smaller dealerships can start by monitoring simple trouble codes and gradually scale to greater remote access and support. He says start with intentional employee training. Build a database of commonly asked questions, and then grow from there. “The goal isn’t just to fix what’s broken. It’s to keep machines running, reduce downtime, and make our techs more effective.”

Learn More

Find more content on United Ag & Turf’s Standalone Support & Solutions Center, visit Farm-Equipment.com/1025.

- Remote Diagnostics: Smarter Service

- UAT’s Proactive Approach Saves Time & Money

- Diversification & Focus: United Ag & Turf Aims to Maximize Performance in Both